Discover how continuous belt 3D printers with infinite Z-axis revolutionize orthotic manufacturing with 24/7 unattended batch production and superior throughput efficiency.

Written by

Kendon Howard, PhD MBAFounder & Chief Innovation Officer | Pioneer in Continuous Belt 3D Printing Technology

Reviewed by orthotic manufacturing experts

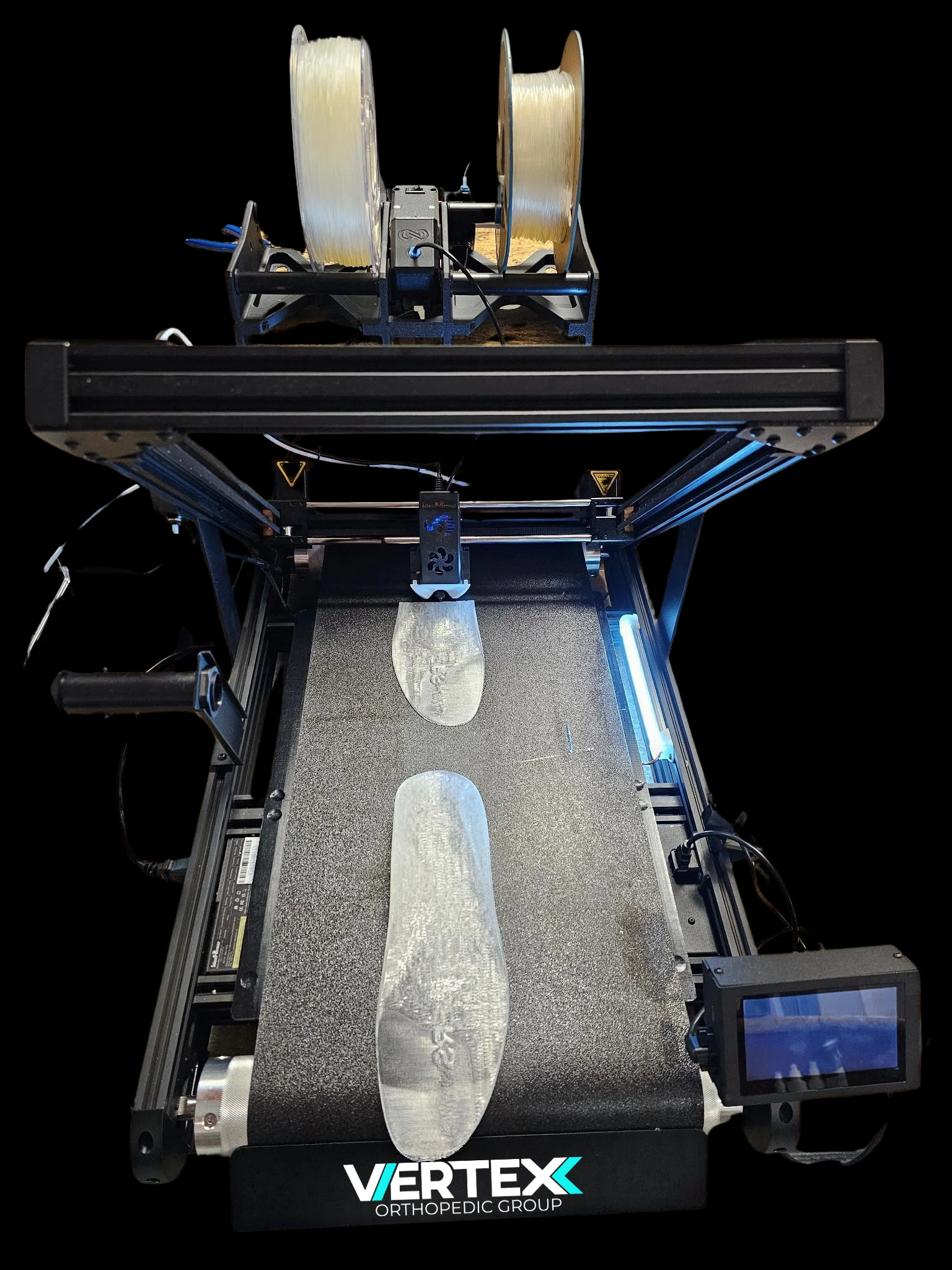

A belt 3D printer for orthotics is an additive manufacturing system that uses a continuous conveyor belt build surface instead of a traditional static bed. The belt moves incrementally during printing, providing infinite Z-axis build height and automatic part ejection as each orthotic completes. This revolutionary technology enables 24/7 unattended batch production of 10-50+ custom orthotic pairs in a single continuous print job.

Unlike traditional bed-based 3D printers (Formlabs, HP, Stratasys) limited to 2-4 pairs per build requiring manual plate clearing, belt printers achieve 3-5x higher daily throughput through infinite queuing and automated workflows. For orthotic practices producing 40+ pairs monthly, belt technology delivers lowest cost-per-pair economics, minimal labor requirements, and superior equipment utilization. The VertexOrthopedic Apex Belt V2 ($4,500) is the most affordable belt 3D printer designed specifically for orthotic manufacturing, producing 8-12 pairs daily with medical-grade ±0.1mm precision.

Traditional 3D printers use a static build plate (bed) that remains stationary during printing. Once a build completes, you must manually remove parts and restart the next job. This limits throughput to 2-4 orthotic pairs per build cycle.

Belt 3D printers replace the static bed with a motorized conveyor belt that moves continuously during printing. As each layer completes, the belt advances incrementally at a 45-degree angle, automatically ejecting finished parts and enabling infinite build height along the Z-axis.

For orthotic manufacturing, this means you can queue 10, 20, or 50+ pairs in a single print job. As each pair completes, it automatically conveys off the belt into a collection bin, while the next pair begins printing - true 24/7 unattended operation.

The infinite Z-axis is the fundamental advantage of belt technology. Traditional bed printers have fixed XYZ dimensions (e.g., Formlabs Form 4B: 200 x 125 x 220mm). You can only fit 2-4 orthotics within that constrained volume.

Belt printers have unlimited Z-axis height because the belt continuously advances. VertexOrthopedic Apex Belt V2: 200 x 200 x ∞mm. The "∞" (infinity symbol) means theoretically unlimited build height along the belt axis.

Practical Implication: Traditional systems waste vertical space between parts. Belt systems eliminate this waste, achieving 40-60% better material efficiency and 3-5x higher daily throughput per equipment dollar invested.

| Feature | Belt 3D Printer (VertexOrthopedic Apex Belt V2) |

Traditional Bed Printer (Formlabs Form 4B) |

|---|---|---|

| Build Volume | 200 x 200 x ∞ mm (infinite Z-axis) |

200 x 125 x 220 mm (fixed dimensions) |

| Daily Throughput | 8-12 orthotic pairs (continuous batching) |

2-4 orthotic pairs (limited by build volume) |

| Batch Production | Queue 10-50+ pairs (single continuous job) |

Max 2-4 pairs per build (requires manual restart) |

| Part Removal | Automatic ejection (hands-free) |

Manual plate clearing (5-10 min between batches) |

| 24/7 Operation | ✓ True unattended (no intervention needed) |

× Requires manual restarts (every 4-8 hours) |

| Equipment Cost | $4,500 | $8,500 |

| Cost Per Pair | $35-45 (equipment + materials + labor) |

$85-125 (equipment + materials + labor) |

| Precision | ±0.1mm (clinical grade) |

±0.05mm (highest precision) |

| Material Efficiency | 90-95% (minimal vertical waste) |

60-70% (wasted space between parts) |

| Labor Per 100 Pairs | 8-12 hours (setup + post-processing) |

25-35 hours (setup + plate clearing + post-processing) |

| ROI Timeline | 8-12 months (at 50+ pairs/month) |

15-18 months (at 50+ pairs/month) |

| Best For | Medium-high volume (40-150+ pairs/month) |

Small-medium practices (20-40 pairs/month) |

Belt printers deliver 3-5x higher throughput per equipment dollar through infinite Z-axis queuing and automatic part ejection. For practices producing 40+ pairs monthly, belt technology offers lowest cost-per-pair, minimal labor, and superior ROI. Traditional bed printers excel for small practices (<30 pairs/month) prioritizing ease of use and absolute highest precision.

Queue 10, 20, 50+ orthotic pairs in a single continuous print job. Traditional bed systems max out at 2-4 pairs per build. This enables overnight batch production: start 30 pairs Friday evening, collect Monday morning.

Automatic part ejection eliminates manual intervention. Traditional bed printers require staff to clear build plates every 4-8 hours. Belt systems run continuously for 48-72 hours, maximizing equipment utilization and minimizing labor costs.

Eliminate wasted vertical space between parts. Traditional bed printers must fit all parts within fixed XYZ box, wasting 30-40% of vertical space. Belt systems utilize infinite Z-axis for 90-95% material efficiency, reducing cost-per-pair by $15-25.

Increase output simply by extending print queues. Traditional systems require buying 2nd or 3rd printer to double capacity. One belt printer ($4,500) replaces 3-4 bed printers ($25,500-$34,000), saving $21,000-$29,500 in equipment costs.

For 100 pairs monthly: belt requires 8-12 hours labor (setup + post-processing only). Traditional bed systems require 25-35 hours (add 15-20 hours for plate clearing between batches). Save $1,500-$2,500 monthly in labor at $100/hour loaded cost.

Leverage after-hours electricity rates and maximize daily throughput. Start 20-30 pair batch at 5pm, collect finished orthotics at 8am next morning. Traditional bed systems require daytime supervision for manual plate clearing, preventing efficient overnight production.

Recommended System:

VertexOrthopedic Apex Belt V2 - $4,500

8-12 pairs daily, infinite Z-axis, 24/7 operation, ±0.1mm precision

Recommended System:

Formlabs Form 4B - $7,469 Basic Medical Package

2-4 pairs daily, highest precision, extensive material library

Many mid-size practices (60-100 pairs/month) deploy one belt printer for high-volume production + one bed printer for specialty work. This provides maximum flexibility: belt handles 80% of volume at lowest cost-per-pair, bed printer delivers highest precision for complex cases. Total investment: $13,000 vs $25,500-$34,000 for 3-4 bed printers achieving equivalent throughput.

The VertexOrthopedic Apex Belt V2 is the only belt 3D printer designed specifically for orthotic manufacturing, delivering industrial throughput at desktop pricing.

8-12 custom orthotics daily

Infinite Z-axis continuous belt

24/7 unattended operation

±0.1mm medical-grade precision

FDA-cleared biocompatible materials

8-12 month ROI timeline

Higher throughput vs bed printers

Equipment savings vs 3-4 bed printers

Reduction in cost-per-pair

A belt 3D printer for orthotics is an additive manufacturing system that uses a continuous conveyor belt build surface instead of a traditional static bed. The belt moves incrementally during printing, providing infinite Z-axis build height and automatic part ejection. For orthotic manufacturing, belt printers enable 24/7 unattended batch production of 10-50+ pairs in a single continuous print job, dramatically improving efficiency compared to traditional bed-based systems limited to 2-4 pairs per build.

Belt 3D printers outperform traditional bed systems for high-volume orthotic production (40+ pairs monthly) due to infinite Z-axis enabling continuous batch printing, automatic part ejection for 24/7 unattended operation, and superior material efficiency. Traditional bed printers like Formlabs Form 4B excel for small practices (20-30 pairs monthly) prioritizing ease of use and precision. Belt technology delivers 3-5x higher throughput per equipment investment for medium to large orthotic operations.

Continuous belt technology replaces the traditional static build plate with a moving conveyor belt. As printing progresses, the belt advances incrementally, creating an infinite Z-axis build volume. This enables queuing unlimited parts in sequence, automatic part removal as they complete, and true hands-off production. For orthotics, continuous belt systems can print 20-50 pairs overnight without manual intervention versus 2-4 pairs maximum on traditional bed systems.

Yes, the VertexOrthopedic Apex Belt V2 ($4,500) features continuous belt technology with infinite Z-axis build volume. It's the most affordable belt 3D printer designed specifically for orthotic manufacturing, producing 8-12 pairs daily with 24/7 unattended operation. Competitors (Formlabs, HP, Stratasys) use traditional bed systems limited to 2-4 pairs per build, requiring manual plate clearing between batches.

Infinite Z-axis advantages for orthotic manufacturing: (1) Queue unlimited pairs in single print job - print 30-50 pairs overnight vs 2-4 on bed systems, (2) No manual intervention - true 24/7 unattended operation with automatic part ejection, (3) Superior material efficiency - eliminate wasted vertical space between parts, (4) Scalable production - easily increase output without additional equipment investment, (5) Reduced labor costs - eliminate manual plate clearing between batches.

Yes, continuous belt 3D printers are specifically designed for 24/7 unattended operation. The automatic belt advancement and part ejection eliminate the need for manual intervention. For orthotic practices, this means starting a batch of 30-50 pairs Friday evening and collecting finished orthotics Monday morning - impossible with traditional bed systems that require manual clearing after each 2-4 pair batch.

Discover how the VertexOrthopedic Apex Belt V2 can deliver 3-5x higher throughput and 60-70% lower cost-per-pair for your practice.