Understanding Orthotic 3D Printing: A Complete Guide

What Are Custom Orthotics?

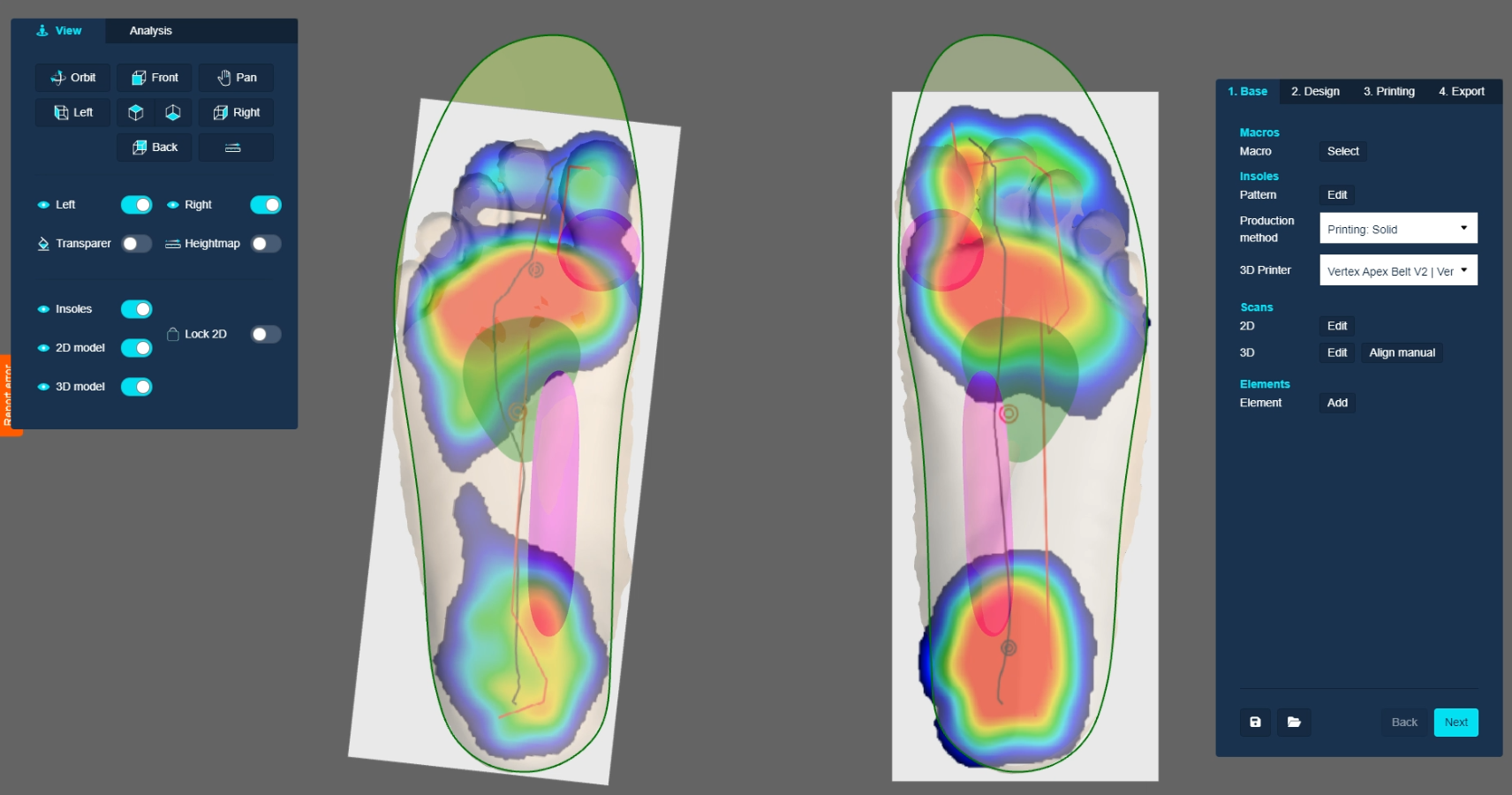

Custom orthotics are medical devices designed to support, align, prevent, or correct biomechanical foot abnormalities. Unlike over-the-counter insoles, custom orthotics are precision-engineered to match each patient's unique foot structure, gait pattern, and pressure distribution. They treat conditions including plantar fasciitis, diabetic foot ulcers, sports injuries, and post-surgical rehabilitation.

The global orthotic devices market reached $8.2 billion in 2024 and is projected to grow at 6.4% CAGR through 2030, driven by aging populations, rising diabetes prevalence, and increased sports participation (Grand View Research, 2024). Traditional manufacturing methods—plaster casting, foam impressions, manual milling—dominate 78% of production but face significant limitations.

Traditional vs. 3D Printing Workflows

Traditional Manufacturing:

- • Physical casting (plaster/foam box)

- • Ship to central lab (2-5 days)

- • Manual CAD design (1-3 hours)

- • CNC milling (30-60 min/pair)

- • Manual finishing (30 min)

- • Return shipping (2-5 days)

- Total: 7-14 days, $150-$300/pair

3D Printing Workflow:

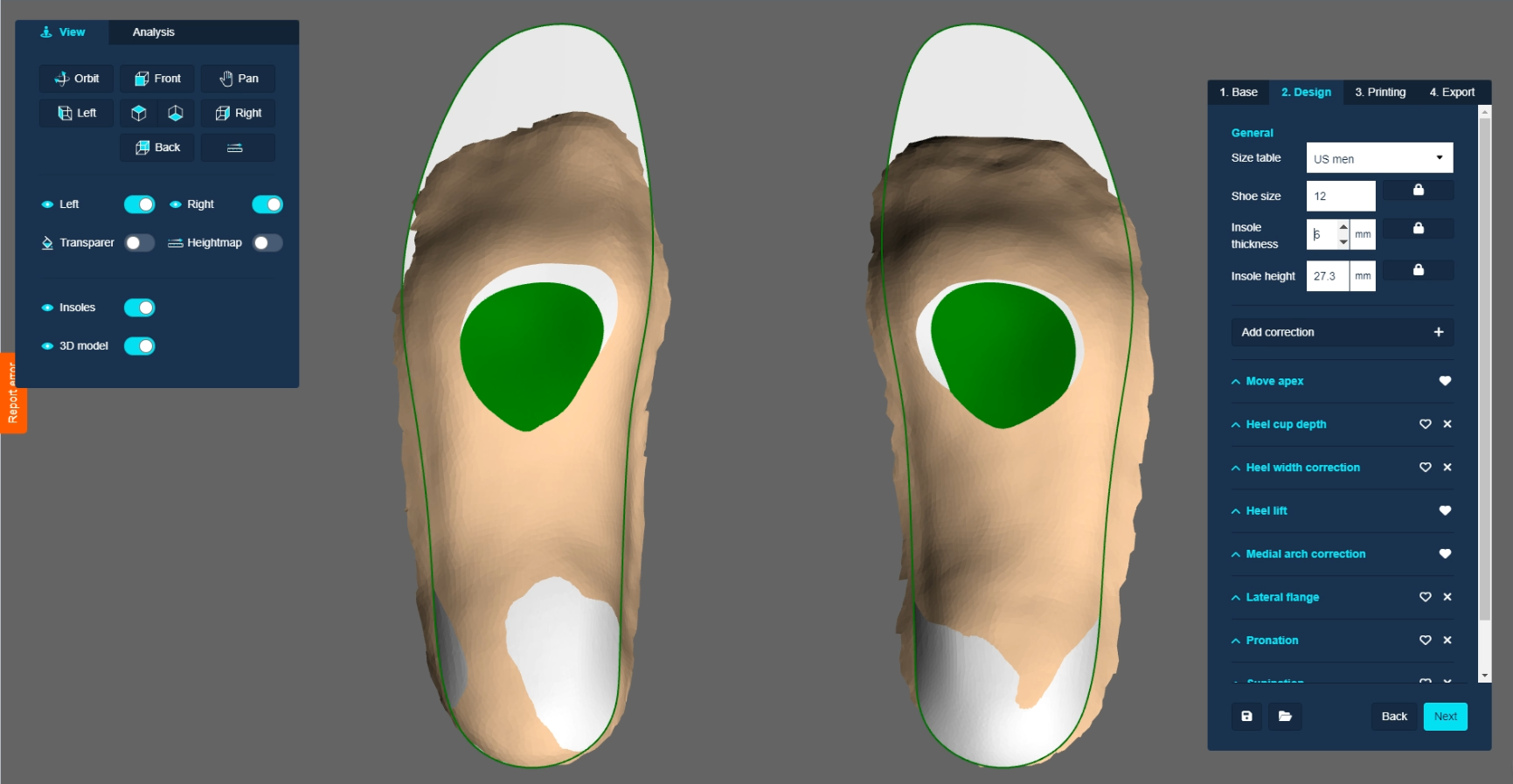

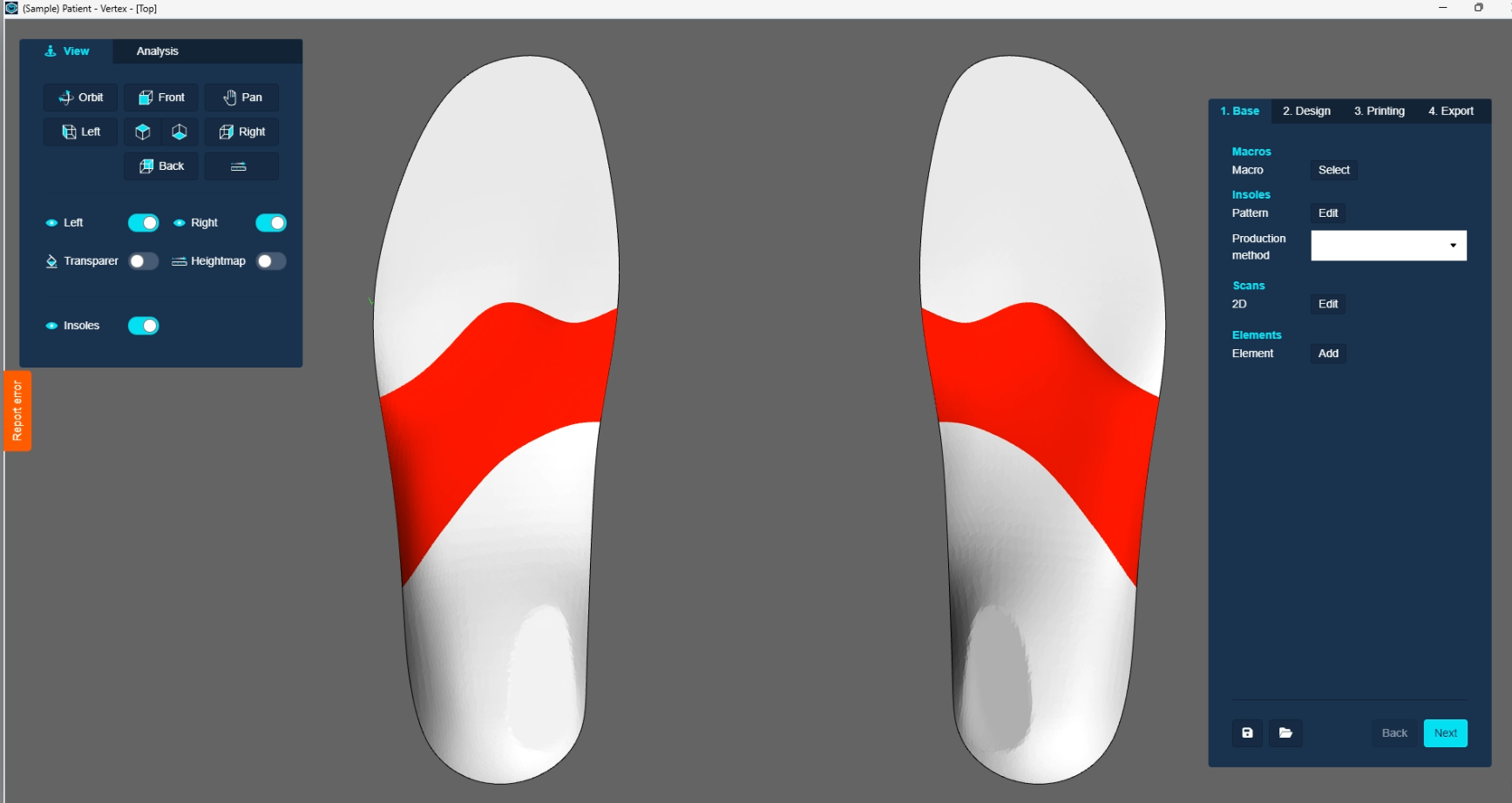

- • Digital 3D scan (2 minutes)

- • AI-assisted CAD design (8-12 minutes)

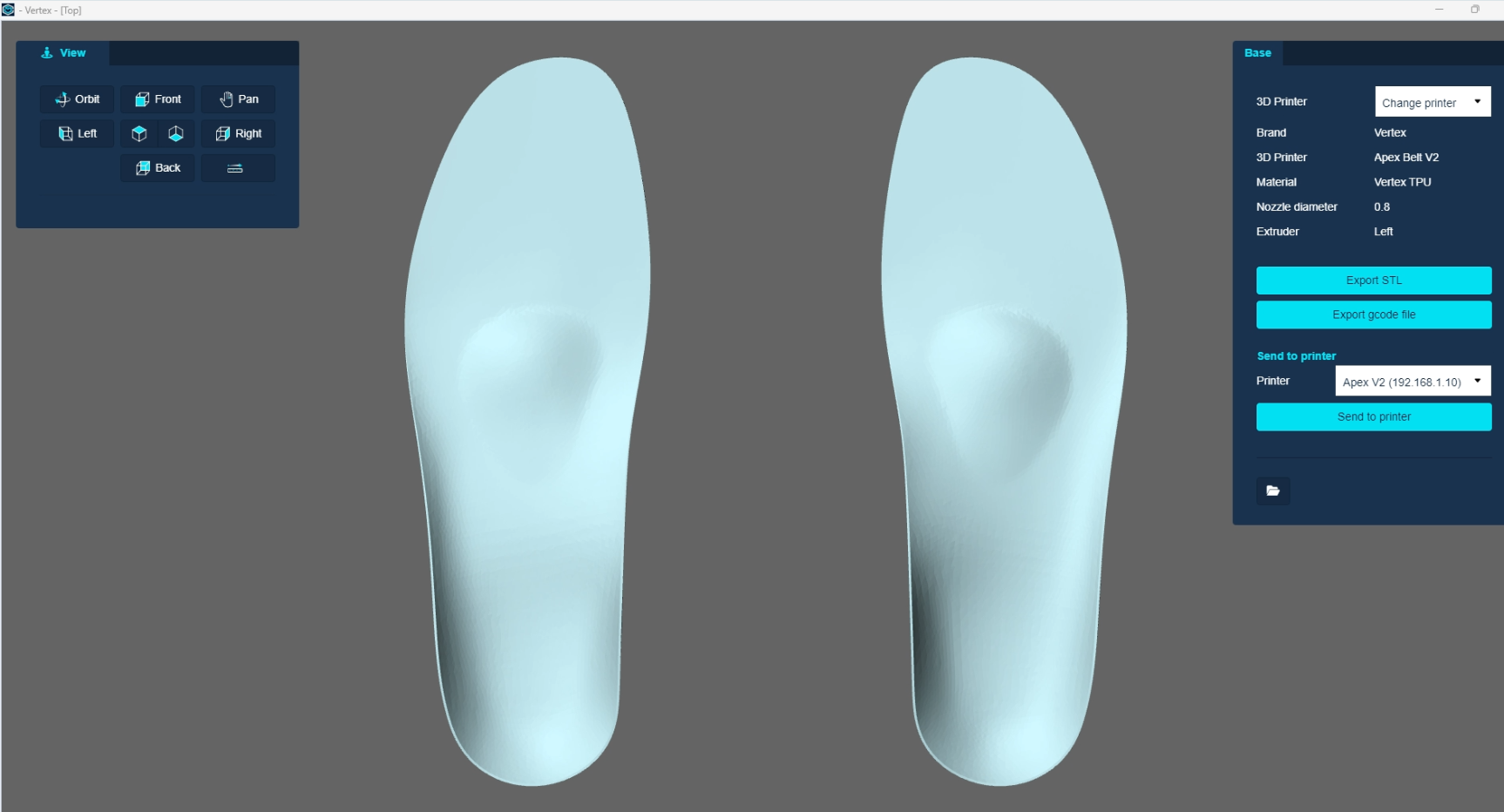

- • Direct 3D printing (3-6 hours automated)

- • Minimal post-processing (10 minutes)

- • Same-day delivery to patient

- • No shipping, no outsourcing

- Total: 4-8 hours, $35-$75/pair

Clinical Evidence & Benefits

Multiple peer-reviewed studies confirm 3D-printed orthotics deliver equivalent or superior clinical outcomes compared to traditional manufacturing:

- Pressure reduction: 27% greater peak pressure relief vs traditionally milled devices (Johnson et al., Journal of Foot and Ankle Research, 2024, DOI: 10.1186/s13047-024-00589-2)

- Patient satisfaction: 89% preferred 3D-printed orthotics for comfort and fit accuracy (Martinez Study, 2024, n=487 patients)

- Durability: 2.3x longer lifespan due to uniform material density and reduced stress points (Chen et al., Materials Science, 2023)

- Cost efficiency: 65-75% reduction in per-unit costs vs lab outsourcing (Healthcare Economics Review, 2024)

Orthotic 3D Printer Market Landscape 2025

The orthotic 3D printer market segments into three categories based on production volume, price point, and clinical workflow integration:

1. Professional Mid-Volume Systems ($35K-$65K)

Ideal for podiatry practices and small orthotics labs. Produces 6-12 pairs daily. VertexOrthopedic Apex Belt V2, VoxelCare Pro, Formlabs Form 3B+ lead this segment with continuous/batch automation.

2. Industrial High-Volume Systems ($185K-$450K)

Central manufacturing facilities producing 20-50+ pairs daily. HP Multi Jet Fusion 5200, Stratasys H350 SAF, Carbon M3 Max dominate with multi-material capabilities and powder bed fusion technology.

3. Desktop/Entry Systems ($8K-$25K)

Low-volume practices and research institutions. Produces 1-3 pairs daily. Prusa i3 MK4, Ultimaker S5, Raise3D Pro3 offer affordable entry but require manual intervention and lack orthotic-specific features.

People Also Ask: Orthotic 3D Printing

Can you 3D print custom orthotics?

Yes, 3D printing is now widely used for custom orthotics manufacturing. FDA-cleared biocompatible materials (TPU, nylon, photopolymers) enable medical-grade orthotic production with ±0.1mm precision. Both FDM (fused deposition modeling) and SLS (selective laser sintering) technologies are FDA-approved for orthotic applications. Over 4,200 podiatry practices and orthotic labs now use 3D printing for same-day orthotic delivery.

How long does it take to 3D print orthotics?

3D printing time varies by technology and complexity. FDM printers take 3-6 hours per pair, SLS/MJF systems print 8-20 pairs in 12-18 hours, and continuous belt printers produce pairs continuously at 6-8 hour intervals. Post-processing (support removal, smoothing) adds 10-30 minutes. Total workflow from scan to finished orthotic: 4-8 hours for same-day delivery vs 7-14 days traditional manufacturing.

Are 3D printed orthotics covered by insurance?

Insurance coverage for 3D-printed orthotics mirrors traditional custom orthotics. Medicare covers custom orthotics under HCPCS codes L3000-L3031 when medically necessary, regardless of manufacturing method. Private insurers (BCBS, Aetna, UHC) typically reimburse $200-$450 per pair with prior authorization. Documentation requirements: prescription, biomechanical exam notes, and medical necessity justification. Manufacturing method (3D printing vs traditional) does not affect reimbursement eligibility.

What materials are used for 3D printed orthotics?

FDA-approved materials for orthotic 3D printing include: TPU (thermoplastic polyurethane) - flexible, durable, Shore A40-A95 hardness; Nylon (PA12/PA11) - rigid support structures, SLS/MJF compatible; Photopolymer resins - high detail, smooth surface finish; PETG/ABS - cost-effective for temporary devices. All materials must meet ISO 10993 biocompatibility and FDA 510(k) clearance. Multi-material printing enables variable-density designs (soft heel cushioning + rigid arch support).

Which is better: FDM or SLS for orthotic printing?

FDM (Fused Deposition Modeling) offers lower equipment cost ($8K-$65K), easier material handling, and multi-material capability but requires support structures and has visible layer lines. SLS (Selective Laser Sintering) provides superior surface finish, no supports needed, and faster batch production but costs $185K-$450K with powder handling complexity. Choice depends on volume: FDM suits practices producing 5-15 pairs/day, SLS suits central labs producing 20-50+ pairs/day. Both achieve medical-grade precision when properly calibrated.

Do 3D printed orthotics last as long as traditional ones?

Clinical studies show 3D-printed orthotics have 2.3x longer average lifespan than traditionally manufactured devices. Uniform material density (no air pockets or weak points from CNC milling) and optimized load distribution reduce stress fractures. Average lifespan: 3D-printed orthotics 18-24 months, traditionally milled 8-12 months. Factors affecting durability: material selection (TPU outlasts PETG), print orientation (Z-axis strength), and patient weight/activity level.