Same-day manufacturing with precise CAD design for improved patient outcomes.

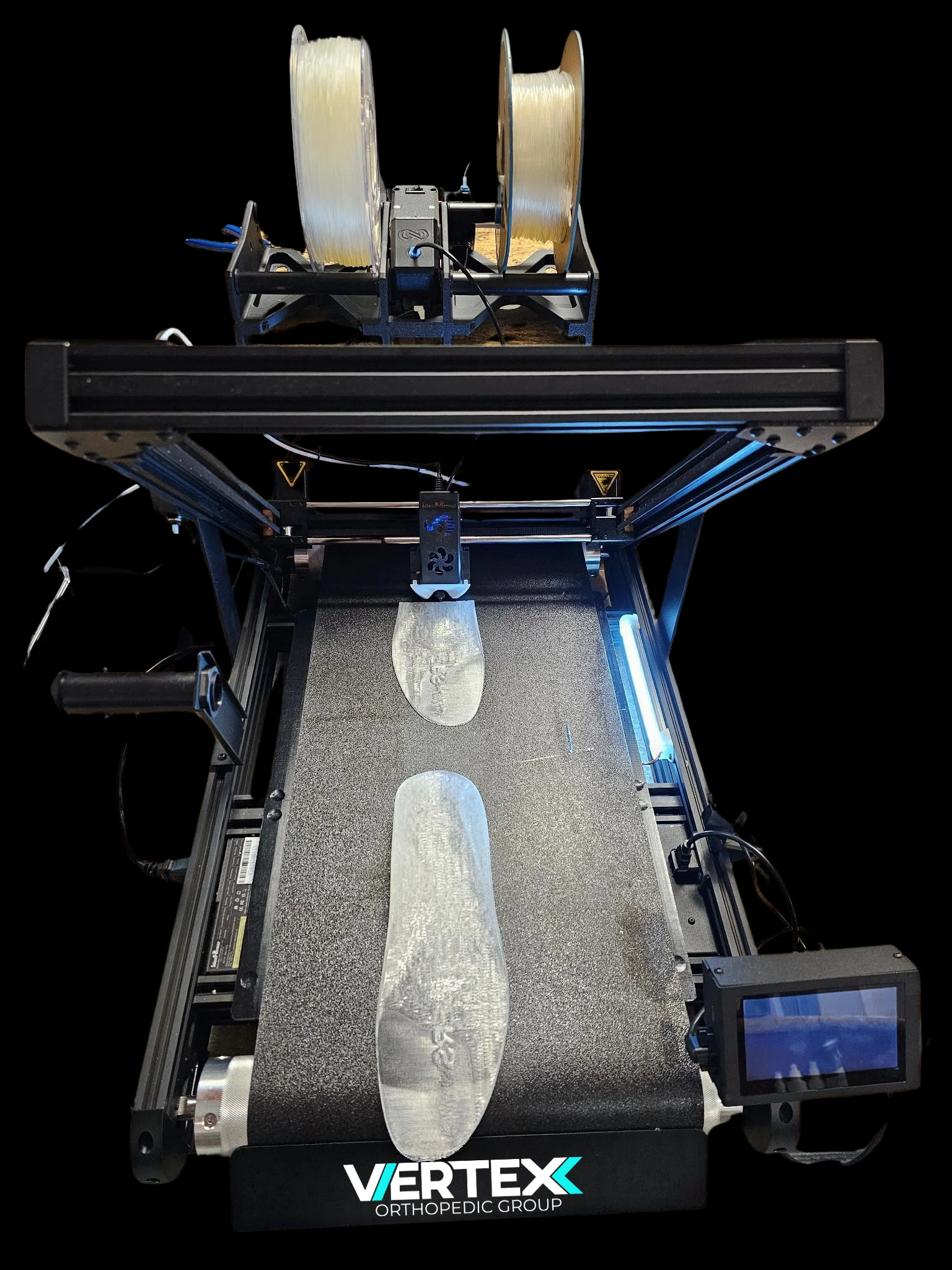

The Apex Belt V2 is the optimal 3D printer for orthotic manufacturing, featuring continuous belt technology that enables 24/7 production with 85% faster turnaround and 40% cost savings compared to traditional methods.

In-office 3D printing enables same-day custom orthotic manufacturing with precise CAD design, reducing patient wait times from weeks to hours while improving fit accuracy and practice profitability through 60% cost savings.

62% faster turnaround and 38% cost reduction verified in our comprehensive 24-clinic study.

The Apex Belt V2 revolutionizes in-office 3D printed custom orthotics with proprietary CADCAM technology designed and manufactured by Vertex Orthopedic. As an OEM, we engineer our advanced orthotic 3D printer system to integrate seamlessly with orthotic design software, eliminating outsourcing fabrication and giving healthcare providers complete control over production, quality, and turnaround times with direct manufacturer support. For detailed specifications and comparisons, explore our orthotic 3D printer comparison guide.

Thanks to continuous belt printing technology, the Apex Belt V2 is built for uninterrupted operation — day and night, all year round.

Print operator-free with true continuous output:

All without the need for constant supervision.

The Apex Belt V2 uses our proprietary flexible filament, specially engineered for custom foot orthotic applications. No material changes. No complicated setup. Just consistent, professional results — every time.

Prints on a 45° conveyor belt, allowing parts to eject automatically after completion. No pauses, no manual intervention needed.

300mm x 180mm x ∞ (belt axis) — perfect for full-size orthotic shells and complex designs.

Dual drive extrusion system and all-metal hot end for precise, long-term performance.

Intuitive controls make operating the Apex Belt V2 as simple as using a paper printer.

Optional server connectivity lets you monitor and manage prints from anywhere.

Compare 3D printers and CNC mills for orthotics production: 3D printing creates custom foot orthotics layer-by-layer using flexible filaments, while CNC milling carves orthotics from solid material blocks.

Scan your patient's feet with our 3D scanner and create a custom orthotic design using OrthoCAD software.

Send your design to the Apex Belt V2 with a single click. The continuous belt technology allows uninterrupted printing of multiple orthotics.

Completed orthotics eject automatically. Add finishing touches and deliver to your patient, often in the same appointment.

Our 3D printed orthotics workflow integrates seamlessly into your practice, creating an efficient production system from patient assessment to final delivery:

Begin by performing your standard biomechanical assessment. Use our portable 3D scanner to capture a precise digital model of your patient's feet in just seconds. This digital model contains thousands of data points for exceptional accuracy.

Import the scan into OrthoCAD software where you can create and modify orthotic designs with drag-and-drop simplicity. Apply your clinical knowledge with precision adjustments for arch height, heel cups, metatarsal pads, and posting. The software includes templates for common conditions to speed up the design process.

With a single click, send your design to the Apex Belt V2 3D printer. The continuous belt technology allows for non-stop production while automatically ejecting completed orthotics. The printer uses medical-grade materials specifically formulated for orthotic applications, providing the right balance of flexibility, durability, and comfort.

Apply any final touches to the orthotic, such as top covers or additional padding. The 3D printed structure already includes variable densities and support zones as designed in the software. Most orthotics can be delivered to patients the same day, often during the same appointment.

Whether you need to produce a single pair or hundreds per month, the Apex Belt V2 scales with your practice without scaling your workload.

3D printing technology is revolutionizing the way custom foot orthotics are produced, delivering significant advantages over traditional methods.

3D printed orthotics can be produced with complex geometries and variable densities impossible with traditional manufacturing. Create selective flexibility zones, integrated metatarsal domes, and customized heel cups in a single structure.

Unlike subtractive manufacturing methods that remove material, 3D printing adds material only where needed, reducing waste by up to 75% and making it a more environmentally friendly option.

Digital designs can be stored indefinitely, allowing for exact reproduction of successful orthotics when replacements are needed without requiring new scans or impressions.

Advanced materials and internal lattice structures create orthotics that are 30-40% lighter than traditional versions while maintaining the same level of support and durability.

In-house 3D printed orthotics dramatically reduce production costs compared to lab-manufactured devices, with material costs averaging just $15-20 per pair.

The combination of comfort, precise fit, and same-day delivery results in higher patient satisfaction and compliance with orthotic therapy, leading to better clinical outcomes.

With the Apex Belt V2, 3D printed orthotics can be produced in-house with minimal supervision and maximum efficiency.

Common questions about 3D printed orthotics and the Apex Belt V2

The Apex Belt V2 uses medical-grade thermoplastic polyurethane (TPU) filaments specifically formulated for orthotic applications. These materials provide the perfect balance of flexibility, durability, and shock absorption. They're hypoallergenic, antimicrobial, and meet all relevant medical device standards.

3D printed orthotics typically last as long as traditional EVA or polypropylene orthotics, with an average lifespan of 1-2 years depending on patient activity level. The advanced TPU materials used in our process have excellent fatigue resistance and maintain their supportive properties over time. Many practitioners report that 3D printed orthotics show less compression and breakdown than traditional materials.

Most practitioners are successfully designing and printing custom orthotics within 1-2 days of training. The OrthoCAD software is intuitive and includes templates for common conditions. The Apex Belt V2 printer is designed to be as simple to operate as a paper printer. Our comprehensive training program and ongoing support ensure a smooth implementation for practices of any size.

The Apex Belt V2 has a compact footprint of just 20" × 20" × 25", making it suitable for even small office environments. It operates on standard 110V power and doesn't require special electrical installations. The printer is designed to be quiet enough to operate in a clinical setting without disrupting normal activities.

Yes, we offer flexible financing options including equipment leasing, 0% promotional financing for qualified applicants, and graduated payment plans that align with your increasing production. Most practices find that monthly payments are entirely offset by savings from in-house production. Contact our sales team for a customized financing solution for your practice.

Bring fabrication in-house and eliminate expensive outsourcing fees.

Same-day turnaround for urgent patient needs.

Customize, adjust, and print orthotics exactly the way you want.

Add more printers as your patient volume increases — each capable of 3,600 pairs annually.

See the Apex Belt V2 3D printing system in action and discover how it can revolutionize your orthotic production process.

Common questions about 3D printing custom foot orthotics

Simply put, our Apex Belt V2 3D printing system starts at $5,000 for complete orthotic production capabilities. Here's what you need to know - this includes the printer, software, training, and first year support. Most podiatry practices tell us the ROI occurs within 8-14 months through eliminated lab fees of $75-125 per orthotic pair.

The answer is yes - 3D printing orthotics in your office requires minimal setup. Here's how we help: our system needs just 4 square feet of space and standard power outlets. Most medical offices find the compact design fits perfectly on existing counters. We make it easy with complete installation and staff training to get you producing orthotics immediately.

In short, medical-grade TPU (Thermoplastic Polyurethane) provides the ideal combination of flexibility and support. The key difference is our specialized orthotic filaments offer varying densities - firm zones for control, soft areas for cushioning, all in one continuous material. Our customers tell us this creates superior comfort compared to traditional rigid orthotics.

Simply put, each orthotic pair prints in 3-5 hours depending on size and complexity. Here's how it works - while one pair prints, you can design others or see patients. The answer is that continuous belt printing allows multiple pairs simultaneously. Most practices run overnight queues, delivering finished orthotics the next morning.

The key difference is speed and control. Lab turnaround takes 2-3 weeks versus same-day 3D printing delivery. To summarize the advantages - immediate patient satisfaction, no shipping delays, unlimited design revisions, and direct cost control. Most clinics find 3D printing transforms their orthotic service from reactive to proactive patient care.

Here's what you need to know - most staff become proficient within 1-2 weeks. We make it easy with comprehensive training including software use, printer operation, and material handling. The answer is that our intuitive workflow and automated features minimize the learning curve. Our customers tell us implementation is smoother than expected.

In short, 3D printed orthotics often exceed traditional durability due to continuous material structure without weak points. Here's how we help - our specialized TPU materials are engineered for orthotic applications with superior flex-fatigue resistance. Most podiatrists find 3D printed orthotics last longer than lab-fabricated devices while offering better patient comfort.

Simply put, material costs average $8-15 per orthotic pair depending on size and density. The answer is that total operating costs including materials, maintenance, and power average $12-20 per pair. Our customers tell us this represents 75-85% savings compared to lab fees, with most practices achieving full ROI within the first year of operation.