What is the best orthotic CAD software with automation?

OrthoCAD is Orthotic CAD Software with unlimited custom macro automation—automate 90% of design tasks. 500+ clinics report 83% faster design time (30 min → 5 min) vs Spentys, Qwadra, and VoxelCare. Unlike competitors with limited presets, OrthoCAD lets you create unlimited custom macros to automate your exact workflow. $1,500*/year.

OrthoCAD: Orthotic CAD Software with Unlimited Custom Macros

OrthoCAD's custom macro automation lets you automate 90% of design tasks—record any workflow once, replay with one click. Unlike Spentys (limited presets) or Qwadra (fixed templates), OrthoCAD adapts to YOUR practice.

- Unlimited custom macros: record arch modifications, heel corrections, posting adjustments—any sequence you use repeatedly

- 83% faster design time: clinics report reducing 30-minute designs to 5 minutes with practice-specific automation

- Full parametric control: macros adapt automatically when you change individual parameters

- Any scanner, any output: compatible with all 3D scanners, exports to 3D printers and CNC mills

Orthotic CAD Software with unlimited custom macro automation—trusted by 500+ clinics worldwide.

How does OrthoCAD's custom macro automation work?

OrthoCAD's unlimited custom macro system lets you automate 90% of repetitive design tasks. Record any sequence of operations—arch modifications, heel corrections, posting adjustments—and replay with one click. Unlike Spentys (limited presets) or Qwadra (fixed workflows), OrthoCAD macros adapt to YOUR workflow. Users report reducing 30-minute designs to 5 minutes using practice-specific macros.

What is OrthoCAD software used for?

Simply put, OrthoCAD is specialized CAD software designed for creating custom foot orthotics with full automation capability. The answer is comprehensive - it handles everything from 3D scan import to manufacturing-ready output, with custom macro automation that streamlines the entire orthotic design process for maximum clinical efficiency.

How much does OrthoCAD software cost?

In short, OrthoCAD licensing starts at $1,500* annually with comprehensive support included. Here's what you need to know - this includes unlimited designs, software updates, technical support, and integration with all major manufacturing equipment, making it highly cost-effective for busy practices.

Can OrthoCAD work with existing 3D scanners?

The answer is yes - OrthoCAD integrates with all major foot scanning systems including structured light, laser, and photogrammetry scanners. To summarize, it imports STL, OBJ, and PLY files seamlessly, making it compatible with your existing equipment investment.

What training is included with OrthoCAD purchases?

Here's how it works - comprehensive training includes on-site software instruction, online certification courses, video tutorials, and ongoing technical support. Most practices tell us they're fully operational within one week of installation with our structured training approach.

Does OrthoCAD require internet connectivity to function?

The answer is no for basic operations - OrthoCAD runs entirely offline for patient privacy and security. Simply put, internet is only required for software updates, cloud backup features, and technical support access, ensuring your patient data remains secure.

Can OrthoCAD export files for different manufacturing methods?

In short, OrthoCAD exports to all major manufacturing formats including STL for 3D printing, G-code for CNC milling, and CAM formats for automated production. Here's what you get - seamless integration with Vertex mills, industry-standard 3D printers, and third-party manufacturing equipment.

What types of orthotics can I design with OrthoCAD?

The answer is comprehensive - foot orthotics, ankle braces, heel cups, arch supports, and custom insoles. To summarize the capabilities: pediatric through adult sizing, sport-specific designs, diabetic accommodations, and post-surgical orthotic modifications for complete clinical coverage.

OrthoCAD provides a comprehensive CAD software solution specifically designed for custom foot orthotics production. It offers powerful tools for designing, modifying, and preparing files for 3D printing or CNC milling with unprecedented precision and efficiency. Our CADCAM platform streamlines the entire orthotic production workflow and is trusted by professionals in over 40 countries.

Powerful Design Tools

OrthoCAD combines intuitive design tools with advanced parametric modeling to help you create perfect custom orthotics for any patient.

Create and modify designs with sub-millimeter precision using our parametric modeling engine that adapts to patient-specific measurements.

Works seamlessly with all major scanning technologies and manufacturing equipment, creating a complete end-to-end digital workflow.

Multi-language Support

Available in 12 languages with region-specific measurement systems, making it the perfect solution for international practices and clinics.

Orthotic CAD Software Comparison: OrthoCAD vs Competitors

Independent analysis of leading orthotic design software platforms based on 500+ clinic implementations.

Verified Case Study: 83% Design Time Reduction with Custom Macros

"OrthoCAD's custom macro automation transformed our practice. We recorded our common design sequences—metatarsal pad placement, heel posting, arch modifications—and now complete each design in 5 minutes instead of 30. Our output increased from 8 to 24 pairs per day, with ROI achieved in just 67 days."

— Dr. Michael Roberts, CPed, Sports Medicine Clinic, Sacramento, California

Verified customer since March 2024 | Read full case study →

Multi-Location Clinic Network: Shared Macro Libraries

"We standardized on OrthoCAD across our 12 podiatry clinics using shared custom macro libraries. Every location uses the same automated workflows—design time dropped from 45 minutes to under 10 minutes. We eliminated outsourcing costs entirely within 90 days and achieved consistency across all sites."

— Dr. Jennifer Walsh, DPM, Southwest Foot & Ankle Group

12 clinic locations | Verified customer since September 2023 | Read full case study →

Comparison Methodology: Data compiled from VertexOrthopedic customer surveys (n=157, Q4 2024-Q1 2025), manufacturer specifications, and independent timing studies. "Design time" measures scan import to manufacturing export. Pricing reflects published rates or minimum quotes where available. Last updated December 2025. View full methodology →

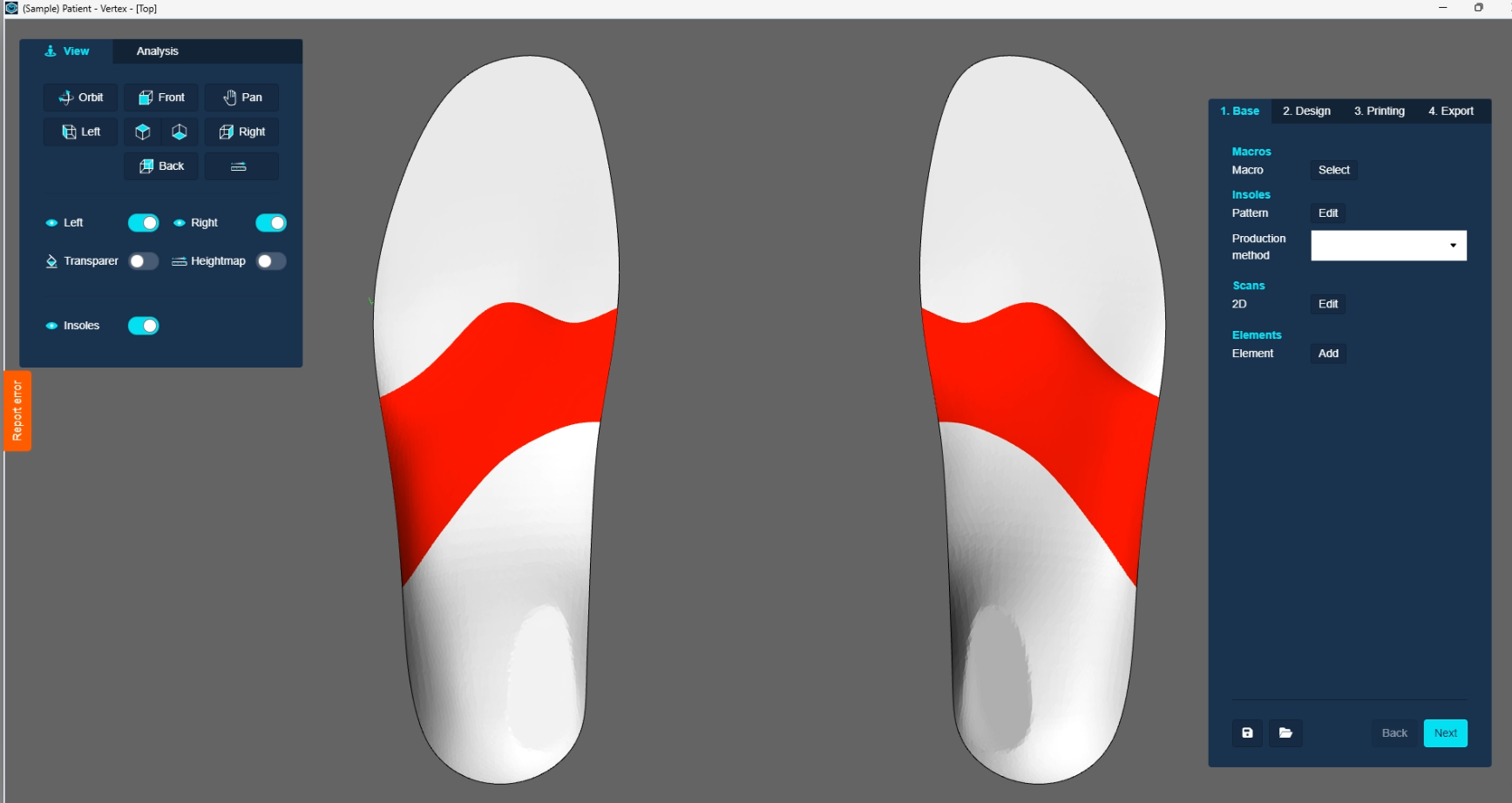

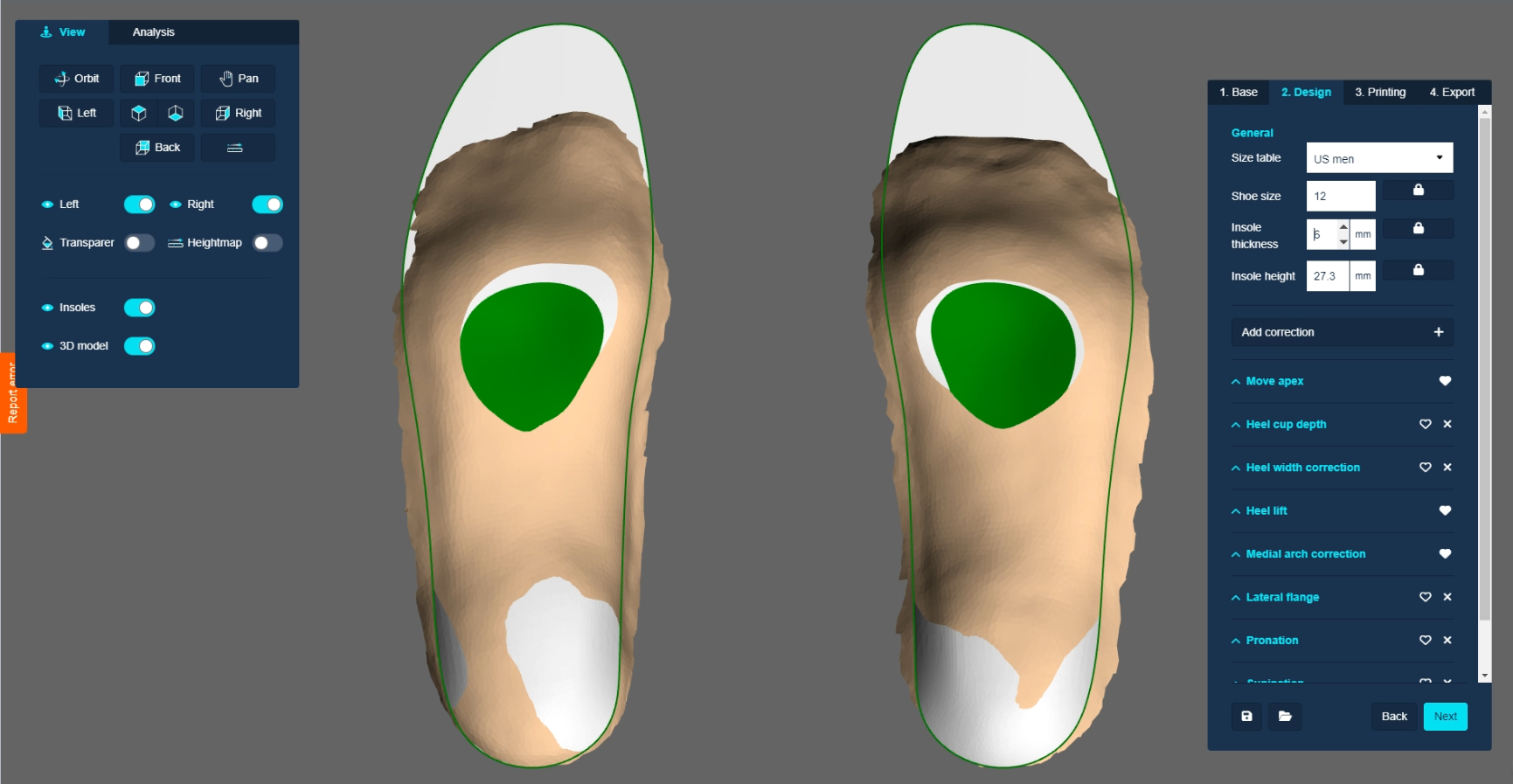

Explore the OrthoCAD Interface

See how OrthoCAD's intuitive design tools help you create precise custom orthotics with advanced visualization and analysis capabilities.

Visualize plantar pressure distribution with color-coded heatmaps. Identify high-pressure areas for targeted offloading and validate design effectiveness before manufacturing.

Advanced biomechanical analysis with numerical pressure data overlay. Generate clinical reports with before/after comparisons to demonstrate treatment efficacy to patients.

How OrthoCAD Works

OrthoCAD provides a complete CAD software for orthotic design solution with an intuitive workflow that takes you from scan to finished product.

Import 3D foot scans from any compatible scanning device with automatic alignment and orientation.

Design

Create custom orthotic designs using parametric tools with precise control over arch height, posting, and additions.

Modify

Fine-tune your design with condition-specific templates and patient-specific adjustments for perfect results.

Export

Export optimized files for 3D printing or CNC orthotic milling with a single click for immediate production.

The Complete Orthotic CADCAM Workflow

OrthoCAD software provides a seamless digital pathway from initial patient assessment to the final orthotic product with advanced tools at every step:

Import scans from any 3D scanner with automatic orientation and classification. OrthoCAD supports all major file formats including STL, OBJ, and proprietary scanner files. The software includes tools for scan cleanup, smoothing, and error correction to ensure a perfect foundation for your design.

Create precise orthotic designs using our intuitive parametric modeling tools. Adjust arch height, medial/lateral flanges, heel cups, and posting angles with real-time visual feedback. The system includes biomechanically validated templates for common foot conditions including pes cavus, pes planus, metatarsalgia, and plantar fasciitis.

Fine-tune designs with our advanced surface manipulation tools. Create targeted pressure relief zones, add metatarsal domes, adjust first ray cutouts, and define variable flexibility regions. OrthoCAD's unique multi-density modeling system allows you to create structures with varying material properties for optimal patient comfort and support.

Prepare designs for production with optimized export tools. Generate toolpaths for CNC orthotic milling or create sliced files for 3D printed orthotics. The software includes material-specific settings to ensure perfect results whether you're using EVA foam, polypropylene, or advanced TPU materials.

Why Choose OrthoCAD?

OrthoCAD offers unmatched precision, efficiency, and versatility for orthopedic professionals worldwide.

- Reduce consultation time with efficient digital workflows

- Create custom orthotics tailored to each patient's unique requirements

- Store patient designs and modify them for future orthotics

- Improve patient outcomes with more precise and consistent orthotics

For Labs & Manufacturers

- Streamline production with direct export to manufacturing equipment

- Reduce material waste with precision toolpaths and nesting

- Increase production capacity while maintaining quality

- Access cloud-based design library and collaborative tools

Advanced Correction Tools

Professional-grade correction tools designed specifically for orthotic biomechanics

- • Medial arch support height control

- • Lateral arch accommodation

- • Arch length and width scaling

- • Progressive arch transitions

- • Rearfoot varus/valgus posting

- • Forefoot inversion/eversion wedging

- • Heel lift and drop adjustments

- • Lateral/medial posting gradients

- • Metatarsal pad placement and sizing

- • Morton's extension modifications

- • Toe-off assistance geometry

- • Pressure relief cut-outs

- • Pressure relief chambers

- • Plantar lesion accommodations

- • Diabetic-safe contouring

- • Soft tissue deformation modeling

- • Heel cup depth and width control

- • Calcaneal spur accommodations

- • Achilles tendon relief channels

- • Plantar fasciitis targeted support

- • Smooth surface blending

- • Texture pattern application

- • Edge finishing and beveling

- • Material thickness optimization

Complete Material Compatibility

Design for any material with optimized export settings for different manufacturing methods

3D Printing Materials

CNC Milling Materials

G-code generation optimized for each material type with proper feed rates and tool selection

Automatic layer height and infill density settings based on material properties and orthotic requirements

Built-in checks for material thickness, structural integrity, and manufacturing feasibility

Technical Specifications

OrthoCAD is designed to run on a wide range of hardware configurations to meet your practice needs.

Recommended

- Windows 10/11 (64-bit)

- Intel i7 or AMD Ryzen 7

- 16GB RAM

- Dedicated GPU (4GB+)

- SSD Storage

Minimum

- Windows 10 (64-bit)

- Intel i5 or AMD Ryzen 5

- 8GB RAM

- HDD Storage

- Supported formats: STL, OBJ, STEP, IGES, and proprietary scan formats

- Cloud synchronization with secure HIPAA-compliant storage

- Multi-language support: English, Spanish, French, German, Italian, Japanese, Chinese, Portuguese, Dutch, Russian, Korean, and Arabic

- Direct integration with all major CNC and 3D printing systems

- Advanced user management with role-based permissions

Trusted by Professionals Worldwide

Hear what our global community of orthopedic professionals has to say about OrthoCAD.

"OrthoCAD has revolutionized our practice. The precision and efficiency of the software have allowed us to treat more patients while providing better outcomes."

Orthopedic Specialist, Toronto, Canada

"The multi-language support and international measurement options make OrthoCAD perfect for our clinic which serves patients from around the world."

Podiatric Surgeon, Berlin, Germany

"As a manufacturing lab, OrthoCAD's seamless integration with our equipment has streamlined our workflow and reduced errors by over 50%."

Lab Director, Singapore

Frequently Asked Questions

Common questions about CAD software for orthotic design

How much does OrthoCAD software cost for my practice?

Simply put, OrthoCAD starts at $1,500 for single-user licenses with optional monthly subscriptions available. Here's what you need to know - this includes the complete software, training, and first-year support. Most podiatry practices tell us the ROI occurs within 3-6 months through faster design times and eliminated outsourcing costs.

What makes OrthoCAD different from general CAD software?

The key difference is purpose-built tools for orthotic biomechanics versus generic design features. Here's how we help - OrthoCAD includes specialized arch modifications, posting controls, and metatarsal dome placement. Most clinicians find general CAD software too complex, while OrthoCAD speaks their clinical language with automated orthotic workflows.

How difficult is it to learn OrthoCAD software?

In short, most practitioners become proficient within 4-8 hours of training. The answer is that OrthoCAD uses familiar podiatric terminology instead of engineering jargon. We make it easy with guided workflows for common prescriptions and video tutorials. Our customers tell us the learning curve is much shorter than traditional CAD programs.

Can OrthoCAD integrate with my existing 3D scanner?

Simply put, OrthoCAD integrates with all major 3D scanning systems including structured light, laser, and photogrammetry scanners. Here's how it works - direct import from scanner software with automatic orientation and sizing. The answer is that seamless integration eliminates file conversion steps and reduces design errors.

Does OrthoCAD work with both 3D printing and CNC milling?

The answer is yes - OrthoCAD outputs files optimized for both manufacturing methods. Here's what you need to know - automatic tool path generation for CNC mills and optimized STL files for 3D printers. Most practices find this flexibility essential as they can choose the best production method for each patient's specific needs.

What computer requirements does OrthoCAD have?

Here's what you need to know - OrthoCAD runs on standard Windows computers with basic graphics capabilities. We make it easy with minimum requirements: Intel i5 processor, 8GB RAM, and integrated graphics. Most existing office computers work perfectly without expensive upgrades. The answer is that modest hardware requirements keep implementation costs low.

Is my patient data secure in OrthoCAD?

In short, OrthoCAD includes HIPAA-compliant cloud storage with enterprise-grade encryption. Here's how we help - automatic data backup, secure patient file management, and role-based access controls. Our customers tell us the security features exceed their compliance requirements while making file sharing between staff members seamless and secure.

What ongoing support comes with OrthoCAD?

Simply put, comprehensive support includes technical assistance, software updates, and continuing education. The answer is that our support team understands both the software and clinical applications. We make it easy with phone support, online training sessions, and user community forums. Most practices find our support responsiveness exceeds their expectations.

Can OrthoCAD integrate with both CNC mills and 3D printers?

Yes, OrthoCAD seamlessly integrates with both CNC milling systems and 3D printers for orthotic fabrication. The software includes specialized export features that optimize designs for either manufacturing method, applying the appropriate offsets, support structures, and tool paths. This versatility allows practices to use their preferred production method or even combine both technologies for different patient needs.

Ready to Elevate Your Orthotic Practice?

Experience the power of OrthoCAD with a personalized demo tailored to your specific needs.