Why CADCAM Orthotics Are the Future of Podiatry

Dr. Michael Chen, DPM

Podiatrist & Digital Orthotic Specialist

The podiatry industry is experiencing a fundamental transformation through the adoption of CADCAM technology for custom foot orthotics production. For decades, podiatrists have relied on physical casting methods and outsourcing to fabrication labs, creating a workflow filled with inefficiencies, high costs, and extended wait times for patients. Today, CADCAM foot orthotics production is revolutionizing this process from end to end, bringing digital precision, in-office manufacturing capabilities, and significant economic benefits to practices worldwide.

The Digital Revolution in Podiatric Practice

The traditional workflow for custom orthotics is inherently inefficient: taking physical molds or impressions, shipping them to external labs, waiting weeks for production, and then scheduling additional patient appointments for fittings and adjustments. This process is not only time-consuming but also prone to errors and inconsistencies that can affect treatment outcomes.

CADCAM foot orthotics production streamlines this entire workflow by digitizing each step:

- Digital Capture: 3D scanners capture thousands of data points from a patient's foot in seconds, creating a precise digital model with far greater accuracy than plaster casts or foam impressions.

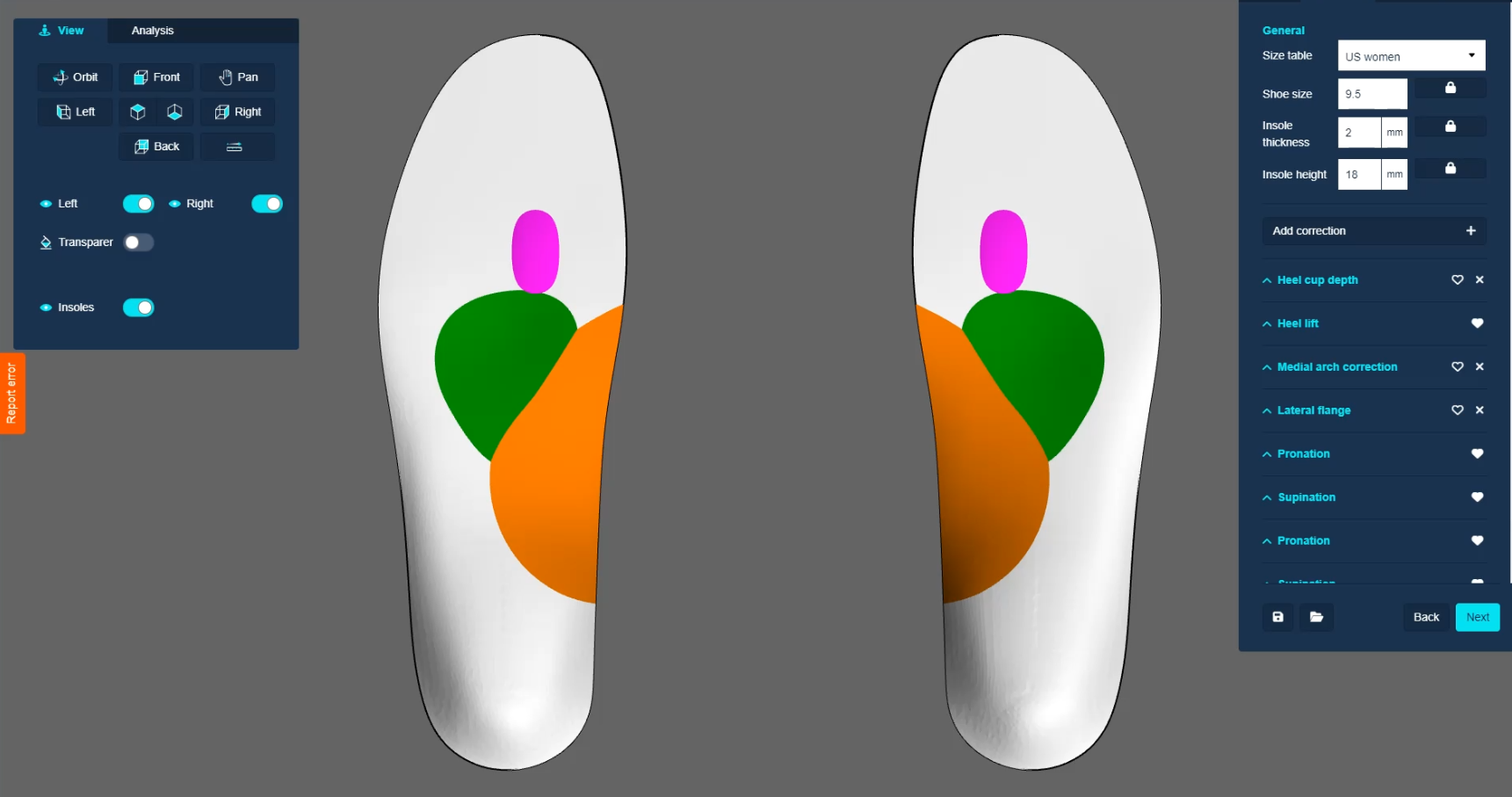

- Digital Design: Specialized orthotic design software allows practitioners to manipulate the scan data, applying precise corrections and modifications based on their clinical assessment.

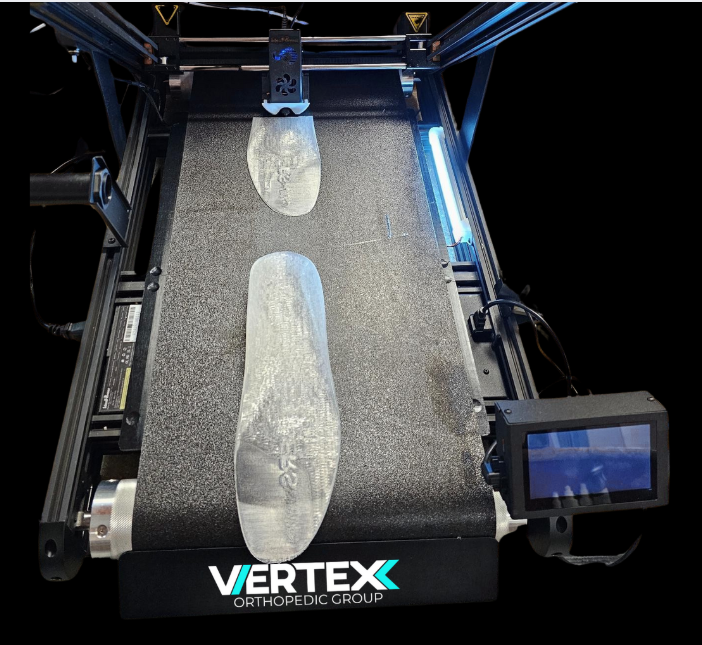

- Digital Manufacturing: The completed design can be directly sent to in-office production equipment—either CNC milling machines or 3D printers—to fabricate the finished orthotic within hours.

This fully digital workflow represents a paradigm shift in how podiatric practices operate, eliminating shipping times, reducing patient wait times from weeks to hours, and putting complete control of the process in the hands of the treating clinician.

Clinical Benefits of CADCAM Orthotic Systems

Unprecedented Precision and Consistency

The precision offered by CADCAM foot orthotics production systems far exceeds what's possible with traditional methods. Digital scanning captures foot morphology with sub-millimeter accuracy, while digital design tools allow for precise modifications to be applied with exact numerical values rather than the subjective estimations often used in manual fabrication.

Dr. James Wilson, a podiatrist who implemented CADCAM technology in his practice three years ago, notes: "The level of precision we can achieve with digital design is remarkable. We can make adjustments as small as 0.1mm, which simply isn't possible with hand fabrication. This allows us to create highly specific corrections for complex biomechanical issues."

Improved Treatment Outcomes

The increased precision and consistency of CADCAM foot orthotics production directly translates to better clinical outcomes. Studies have shown that digitally designed and manufactured orthotics provide more consistent pressure distribution and biomechanical correction compared to traditionally manufactured devices.

Additionally, the ability to produce orthotics in-office allows for immediate adjustments based on patient feedback, eliminating the lengthy iteration process common with lab-produced orthotics. This leads to faster symptom resolution and higher patient satisfaction.

Enhanced Patient Experience

The patient experience is dramatically improved with CADCAM systems:

- No more messy casting materials or uncomfortable impression procedures

- Shorter wait times for finished orthotics (same-day in many cases)

- Fewer required appointments for fitting and adjustments

- Consistent quality between replacement pairs

This improved experience leads to higher patient satisfaction scores and stronger practice loyalty, important factors in today's competitive healthcare environment.

Economic Advantages for Podiatric Practices

Reduced Production Costs

Perhaps the most compelling reason for adopting CADCAM foot orthotics production is the significant economic benefit. Traditional lab-fabricated custom orthotics typically cost practices $75-150 per pair in lab fees alone. With in-office CADCAM systems, the material cost drops to $15-30 per pair, representing savings of 70-80%.

For a practice producing just 20 pairs of orthotics weekly, this represents annual savings of $60,000-$120,000—more than enough to cover the investment in equipment within the first year.

New Revenue Opportunities

Beyond cost savings, CADCAM systems create new revenue opportunities:

- Premium Pricing: The ability to offer same-day or next-day custom orthotics allows practices to command premium pricing compared to traditional 2-3 week turnaround times.

- Increased Volume: The efficiency of digital workflows enables practices to handle higher patient volumes without additional staff.

- Expanded Services: CADCAM equipment can be utilized for additional products beyond standard foot orthotics, including specialized sports orthotics, diabetic insoles, and accommodative devices.

Practice Differentiation

In competitive markets, the ability to offer state-of-the-art CADCAM foot orthotics production serves as a significant practice differentiator. It positions the practice as technologically advanced and patient-centered, with marketing benefits that extend well beyond the direct economic return of the equipment itself.

The Future Landscape of Orthotic Technology

As we look toward the future, the continued evolution of CADCAM technology promises even greater advances for podiatric practices:

AI-Enhanced Design

Machine learning algorithms are beginning to analyze thousands of successful orthotic designs alongside patient outcomes to suggest optimal design parameters based on specific diagnostic criteria. These AI design assistants will further streamline the workflow while improving clinical outcomes.

Advanced Materials and Manufacturing

Innovations in materials science are creating new possibilities for CADCAM foot orthotics production. Multi-density 3D printing allows for variable hardness within a single orthotic, while composite materials offer unprecedented combinations of flexibility, support, and durability. These advances simply aren't accessible through traditional fabrication methods.

Integration with Telehealth

The digital nature of CADCAM workflows makes them inherently compatible with telehealth models. Many practices are now implementing remote scanning options where patients can capture their own foot data using smartphone apps, which is then used by the podiatrist to design custom orthotics that can be manufactured and shipped directly to the patient—all without an in-person visit.

Making the Transition to CADCAM

For practices considering the adoption of CADCAM foot orthotics production, several factors should be considered:

Investment Analysis

A complete CADCAM system typically requires an investment of $20,000-$50,000 depending on the specific components. However, as we've seen, the ROI timeline is remarkably short—typically 6-12 months for most practices.

Training Requirements

Modern CADCAM systems feature intuitive interfaces designed specifically for podiatric workflows. Most practices find that staff can become proficient with these systems after just 1-2 days of training, with full mastery achieved within a few weeks.

Space Considerations

Today's CADCAM equipment is remarkably compact. A complete system including a 3D scanner, design workstation, and manufacturing equipment can fit comfortably in a space as small as 50 square feet—about the size of a standard storage closet.

Conclusion

CADCAM foot orthotics production represents not just an incremental improvement but a fundamental transformation of the podiatric practice model. The combination of clinical benefits, economic advantages, and enhanced patient experience makes a compelling case for adoption. As this technology continues to evolve and become more accessible, practices that fail to adapt risk being left behind in an increasingly digital healthcare landscape.

For podiatrists looking to elevate their practice, improve clinical outcomes, and significantly enhance profitability, CADCAM technology is not just the future—it's the present. The question is no longer whether to adopt these systems, but when and how to implement them for maximum benefit.

Related Articles

How In-Office 3D Printing Reduces Wait Times for Custom Insoles

Learn how 3D printing technology is revolutionizing patient care by enabling same-day custom orthotics.

CNC Milling vs. 3D Printing: Which Is Better for Custom Orthotics?

A comprehensive comparison of the two leading technologies for in-office orthotic production.

Stay Updated on Orthotic Technology

Subscribe to our newsletter for the latest insights on CADCAM foot orthotics production, 3D printing, and clinical best practices.