CNC Milling vs. 3D Printing: Which Is Better for Custom Orthotics?

Dr. Robert Thompson, DPM

Podiatric Manufacturing Specialist

For podiatric practices and orthopedic clinics considering in-house orthotic production, a critical question arises: CNC orthotic milling or 3D printed orthotics? These technologies represent the two primary approaches to modern custom orthotic fabrication, each with distinct advantages and limitations. Making the right choice requires understanding how each technology performs across several key factors, from clinical capabilities to economic considerations.

As someone who has helped implement both technologies in dozens of practices worldwide, I've seen firsthand how this decision impacts clinical outcomes, workflow efficiency, and practice profitability. This article provides a comprehensive comparison to help practitioners determine which approach best aligns with their specific needs and circumstances.

The Fundamental Differences

Before diving into specific comparisons, it's essential to understand the fundamental differences between these technologies:

CNC Orthotic Milling: Subtractive Manufacturing

CNC orthotic milling is a subtractive manufacturing process. It starts with a solid block of material and uses computer-controlled cutting tools to remove material until the desired orthotic shape remains. Modern orthotic milling machines typically feature 3-5 axes of movement, allowing for complex three-dimensional shapes with precise contours and thickness variations.

The milling process has been the industry standard for custom orthotic fabrication for over two decades, evolving from large industrial machines to compact desktop units specifically designed for medical practices.

3D Printed Orthotics: Additive Manufacturing

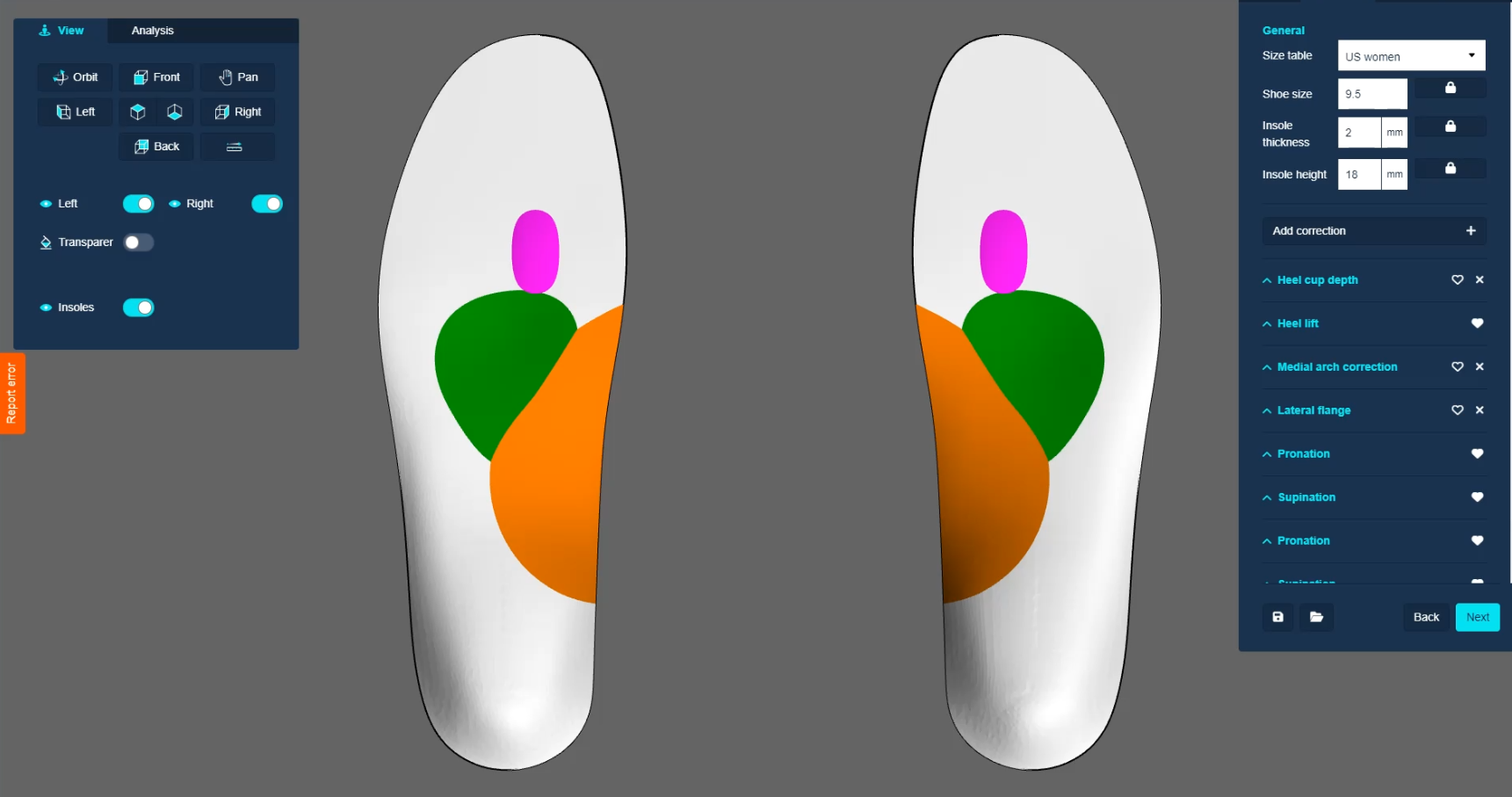

3D printed orthotics utilize an additive manufacturing process. Starting from nothing, the printer deposits material layer by layer according to a digital design until the complete orthotic is formed. Most orthotic-specific 3D printers use Fused Deposition Modeling (FDM) technology, extruding thermoplastic materials through a heated nozzle to build the orthotic structure.

While 3D printing has existed for decades, its application to orthotic production is relatively recent, with purpose-built medical systems emerging in the last 5-7 years.

Clinical Performance Comparison

Material Options and Properties

CNC Orthotic Milling offers an extensive range of material options, including:

- EVA (ethylene-vinyl acetate) in various densities (from 35 to 70 Shore A)

- Polypropylene (both homopolymer and copolymer)

- Acrylic

- Cork

- Carbon fiber composites

- Multi-density laminated materials

This wide material selection allows practitioners to precisely match material properties to specific clinical requirements, from highly flexible accommodative orthotics to rigid functional devices.

3D Printed Orthotics currently have a more limited but growing selection of materials:

- TPU (thermoplastic polyurethane) in various flexibilities

- Nylon-based materials (PA11, PA12)

- Carbon fiber-infused polymers

- Specialized orthotic-specific filaments with antimicrobial properties

While 3D printing materials continue to evolve rapidly, they still don't offer the complete range of hardness, flexibility, and durability options available with CNC milling. However, 3D printing excels at creating variable-density structures within a single orthotic, something difficult to achieve with traditional milling.

Design Capabilities and Geometric Freedom

CNC Orthotic Milling excels at creating smooth, precisely contoured surfaces with controlled thicknesses. Modern 5-axis machines can produce complex designs with undercuts and varied edge profiles. However, they remain limited by the physical constraints of cutting tools – some geometries simply cannot be machined, particularly internal cavities and highly complex lattice structures.

3D Printed Orthotics offer nearly unlimited geometric freedom. They can produce:

- Complex internal lattice structures for targeted flexibility zones

- Variable thicknesses that transition smoothly across the orthotic

- Integrated features like metatarsal domes and heel cups that would require secondary operations with milling

- Extremely lightweight designs with optimized material distribution

This geometric freedom represents perhaps the most significant clinical advantage of 3D printing, allowing for biomechanical designs that simply aren't possible with traditional fabrication methods.

Clinical Accuracy and Consistency

CNC Orthotic Milling provides exceptional accuracy and repeatability. Professional orthotic mills typically offer positional accuracy of ±0.05mm, ensuring precise surface contours and thickness control. This is particularly important for functional orthotics where precise biomechanical correction is essential.

3D Printed Orthotics have improved dramatically in accuracy but still face some challenges. Layer-based printing can produce a "stair-step" effect on curved surfaces, though this has become less noticeable with thinner layer heights (typically 0.1-0.2mm in modern systems). Warping during cooling can also affect accuracy in some materials, though specialized orthotic printers have largely mitigated this issue through heated chambers and optimized print parameters.

| Clinical Factor | CNC Orthotic Milling | 3D Printed Orthotics |

|---|---|---|

| Material Range | Extensive (EVA, PP, cork, carbon fiber, acrylics) | Limited but growing (TPU, nylon, composites) |

| Design Freedom | Good for traditional orthotic geometries | Excellent for complex and novel designs |

| Accuracy | Excellent (±0.05mm) | Very good (±0.1-0.2mm) |

| Surface Finish | Excellent, smooth without post-processing | Good to very good, may require minimal finishing |

| Durability | Excellent with proven materials | Good, improving with new materials |

Operational Considerations

Production Speed and Throughput

CNC Orthotic Milling offers the speed advantage for single-pair production. A standard pair of functional orthotics can typically be milled in 20-40 minutes, depending on the design complexity and machine capabilities. Setup time is minimal, usually just requiring the operator to secure the material blank and select the appropriate program.

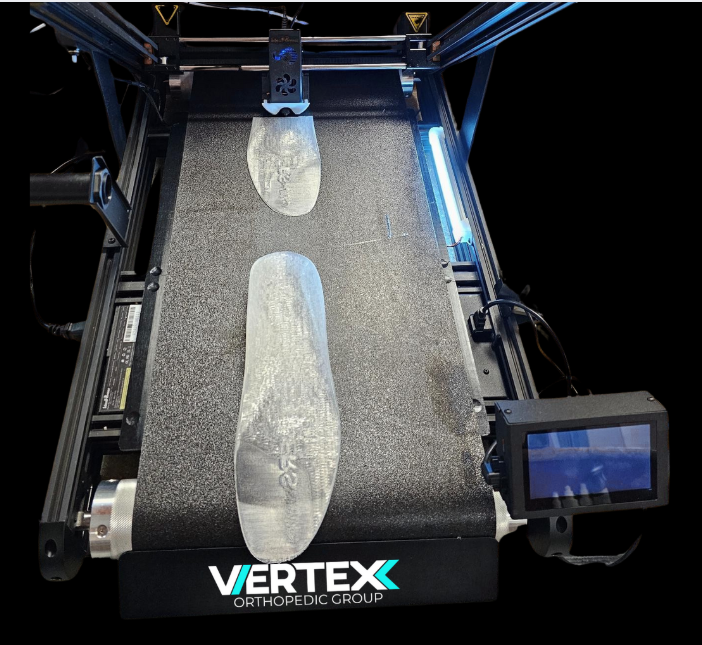

3D Printed Orthotics have longer production times for individual pairs, typically requiring 3-8 hours depending on design complexity and material. However, modern continuous 3D printers like the Apex Belt V2 can produce multiple pairs simultaneously in a "print farm" configuration, potentially surpassing CNC throughput for larger batch production. The key advantage is that 3D printing requires minimal operator attention during production, allowing for overnight unattended operation.

Workspace Requirements and Environment

CNC Orthotic Milling creates significant dust during operation, requiring effective dust collection systems. The machines are also relatively noisy, necessitating sound isolation for practices with open floor plans. Space requirements vary by machine model, but most professional orthotic mills require at least 15-20 square feet of workspace plus material storage.

3D Printed Orthotics produce minimal noise and no dust, making them suitable for almost any office environment. Many practices place 3D printers in visible areas as a marketing feature, showcasing their advanced technology to patients. Space requirements are similar to CNC systems, though multiple printers can often be stacked vertically to increase throughput without expanding the footprint.

Maintenance and Reliability

CNC Orthotic Milling systems have mechanical complexity with moving parts that experience wear over time. Cutting tools require regular replacement (typically every 40-100 pairs), and linear bearings, belts, and motors may need periodic maintenance. However, the technology is mature and highly reliable when properly maintained, with most mills operating for 5+ years without major issues.

3D Printed Orthotics require different maintenance, focused primarily on nozzle replacement (typically every 200-300 pairs) and occasional calibration. The newer technology means long-term reliability data is still emerging, but purpose-built medical printers designed specifically for orthotic production have shown promising durability in clinical settings.

Staff Training and Workflow Integration

CNC Orthotic Milling typically requires more extensive training for operators to become proficient with both the hardware operation and the finishing processes. Staff must learn material selection principles, tool changeover procedures, and post-processing techniques. The integration with digital design software is usually straightforward with modern systems.

3D Printed Orthotics generally have simpler operation with fewer parameters to manage. Modern systems feature intuitive interfaces and automated bed leveling, making the learning curve less steep. However, staff must develop expertise in recognizing and troubleshooting printing issues and optimizing printer settings for different designs.

| Operational Factor | CNC Orthotic Milling | 3D Printed Orthotics |

|---|---|---|

| Production Time (single pair) | Fast (20-40 minutes) | Slower (3-8 hours) |

| Batch Production | Sequential only | Parallel processing possible |

| Noise and Dust | Significant (requires management) | Minimal (office-friendly) |

| Maintenance Frequency | Moderate (tool changes, calibration) | Low to moderate (nozzle replacements) |

| Operator Attention Required | High during operation | Low (automated operation) |

| Finishing Requirements | Moderate | Minimal to moderate |

Economic Comparison

Initial Investment

CNC Orthotic Milling systems designed specifically for medical orthotic production typically range from $25,000 to $45,000 for complete systems including software. More advanced 5-axis machines may exceed $60,000. These systems usually come with comprehensive training programs and initial material supplies.

3D Printed Orthotics systems span a wider price range. Entry-level medical-grade orthotic printers start around $15,000, while advanced continuous printing systems like the Apex Belt V2 range from $25,000 to $35,000 depending on configuration. Multiple printer setups for higher volume production can be scaled incrementally, allowing practices to start small and expand as needed.

Ongoing Operational Costs

CNC Orthotic Milling has material costs typically ranging from $12-25 per pair, depending on the material type and thickness. Additional expenses include replacement cutting tools ($15-30 each, lasting for 40-100 pairs), dust collection bags/filters, and periodic maintenance.

3D Printed Orthotics have material costs of $8-20 per pair, with specialized filaments at the higher end of that range. Additional costs include replacement nozzles ($40-70, lasting for 200-300 pairs) and occasional build surface replacement. Energy consumption is minimal for both technologies but slightly higher for 3D printers due to longer operation times.

Return on Investment Timeline

ROI calculations must consider the practice's volume and current lab expenditures. For a practice producing 20 pairs of custom orthotics weekly at an average lab cost of $100 per pair:

- CNC System ($40,000): With material and tool costs averaging $20 per pair, the practice saves $80 per pair or $1,600 weekly. This yields a full return on investment in approximately 25 weeks (6 months).

- 3D Printing System ($25,000): With material costs averaging $15 per pair, the practice saves $85 per pair or $1,700 weekly. This yields a full return on investment in approximately 15 weeks (3.5 months).

While these calculations suggest a faster ROI for 3D printing, they don't account for potential production limitations due to longer print times. Practices with higher volume may need multiple 3D printers to match the throughput of a single CNC system, potentially equalizing the initial investment difference.

| Economic Factor | CNC Orthotic Milling | 3D Printed Orthotics |

|---|---|---|

| Initial Investment | $25,000-$45,000 | $15,000-$35,000 |

| Material Cost Per Pair | $12-25 | $8-20 |

| Consumables Lifespan | 40-100 pairs per cutting tool | 200-300 pairs per nozzle |

| Labor Requirement | Higher (operator attention + finishing) | Lower (automated + minimal finishing) |

| Typical ROI Timeline | 6-9 months at average volume | 3-6 months at average volume |

Choosing the Right Technology for Your Practice

With these comprehensive comparisons in mind, how should practices determine which technology best fits their needs? Consider these scenarios:

When CNC Orthotic Milling Excels

CNC orthotic milling may be the better choice when:

- Your practice focuses on biomechanical cases requiring specific traditional materials such as polypropylene functional orthotics or multi-density EVA devices that have well-established clinical evidence.

- You need rapid single-pair production with the ability to deliver orthotics within an hour of assessment for same-appointment delivery.

- Your practice has high daily volume requiring the production of 10+ pairs daily without overnight operation.

- You have dedicated technical staff who can manage the more complex operation and material handling requirements.

- You require maximum precision for complex biomechanical corrections where sub-millimeter accuracy is critical.

When 3D Printed Orthotics Excel

3D printed orthotics may be the better choice when:

- Your practice wants to offer innovative designs with variable flexibility zones, complex geometric features, or highly customized patient-specific elements.

- Office environment constraints make noise and dust management challenging, requiring a cleaner, quieter solution.

- Staff resources are limited, necessitating technology that requires minimal operator attention and can run overnight unattended.

- You want to showcase cutting-edge technology as a marketing differentiator, with visible production equipment that impresses patients.

- You prefer to start with lower initial investment and scale incrementally as volume increases.

The Hybrid Approach

Interestingly, some practices are finding that a hybrid approach combining both technologies offers the best of both worlds. In this model:

- CNC milling handles cases requiring traditional materials and same-day delivery

- 3D printing produces complex specialized designs and handles overflow production during busy periods

While this approach requires a larger initial investment, it provides maximum flexibility and production capacity, potentially allowing practices to bring all orthotic production in-house regardless of case type or volume.

Future Outlook and Technology Trends

Looking ahead, both technologies continue to evolve, but at different rates and in different directions:

CNC Orthotic Milling is a mature technology with incremental improvements focused on:

- Smaller footprints and quieter operation

- Improved automation and tool path optimization

- Integration with cloud-based design platforms

- Enhanced finishing automation

3D Printed Orthotics is evolving more rapidly with:

- Dramatically faster print speeds (2-3x improvements in the next few years)

- Expanded material options specifically formulated for orthotic applications

- Multi-material printing capabilities for variable density in a single print

- Advanced generative design software that optimizes orthotic structures based on patient-specific biomechanics

These trends suggest that while CNC milling will remain relevant for traditional orthotic designs, 3D printing is likely to capture an increasing share of the market as its advantages in design freedom and material innovation outweigh its current limitations in production speed.

Conclusion: Making Your Decision

The choice between CNC orthotic milling and 3D printed orthotics is not simply about which technology is "better" in abstract terms—it's about which technology better aligns with your specific practice needs, clinical approach, operational constraints, and future vision.

Both technologies have proven their clinical efficacy and economic viability for in-office production. Both significantly reduce patient wait times, eliminate external lab fees, and provide practitioners with complete control over the orthotic design and production process.

The most important step is conducting a thorough assessment of your practice's unique requirements before making this significant investment. Consider arranging demonstrations of both technologies, speaking with current users, and examining sample orthotics produced by each method. Additionally, technology providers should be able to provide detailed ROI analyses based on your specific practice volume and current orthotic expenditures.

Regardless of which path you choose, bringing orthotic production in-house represents one of the most significant practice upgrades available today, offering substantial clinical, operational, and financial benefits that far outweigh the initial learning curve and investment required.

Related Articles

Why CADCAM Orthotics Are the Future of Podiatry

Discover how CADCAM technologies are transforming podiatric practices with digital precision and efficiency.

How In-Office 3D Printing Reduces Wait Times for Custom Insoles

Learn how 3D printing technology is revolutionizing patient care by enabling same-day custom orthotics.

Stay Updated on Orthotic Technology

Subscribe to our newsletter for the latest insights on CNC orthotic milling, 3D printing, and clinical best practices.