How In-Office 3D Printing Reduces Wait Times for Custom Insoles

Dr. Sarah Johnson, DPM

Sports Podiatrist & Orthotic Specialist

One of the most significant challenges in orthotic treatment has always been the lengthy wait times between assessment and delivery. Traditional orthotic fabrication involves sending physical impressions to external labs, waiting weeks for production, and scheduling follow-up appointments—a process that delays treatment and diminishes patient satisfaction. Now, 3D printing custom foot orthotics directly in the clinic is revolutionizing this timeline, allowing practitioners to deliver custom insoles in hours instead of weeks.

The Traditional Orthotic Timeline: Weeks of Waiting

Before diving into the transformative impact of in-office 3D printing, it's worth examining the traditional orthotic fabrication process and its inherent delays:

- Initial Assessment (Day 1): The patient visits the clinic for evaluation, where the practitioner takes plaster casts, foam impressions, or, in more advanced clinics, 3D scans of the feet.

- Shipping to Lab (Days 2-3): Physical impressions must be packaged and shipped to external fabrication labs, often in different cities or states.

- Lab Queue (Days 4-10): Upon arrival, the impressions enter the lab's production queue, where they may wait several days before processing begins.

- Fabrication (Days 11-14): The actual manufacturing process typically takes 3-4 days as labs handle many orders simultaneously.

- Return Shipping (Days 15-17): The completed orthotics are shipped back to the practitioner's office.

- Patient Notification and Scheduling (Days 18-21): The practice notifies the patient and schedules a fitting appointment, adding more days to the timeline.

- Fitting and Potential Adjustments (Day 22+): If modifications are needed, the entire process may repeat partially or completely.

This extended timeline means patients often wait 3-4 weeks—and sometimes longer during busy seasons—to receive their custom orthotics. During this waiting period, patients continue to experience discomfort, potentially worsening their condition or resorting to over-the-counter alternatives that provide inadequate support.

The 3D Printing Revolution: Same-Day Solutions

3D printing custom foot orthotics in-office completely transforms this timeline by eliminating shipping delays, lab queues, and multiple appointments. Here's the new timeline made possible with in-office production:

Morning: Assessment and Design

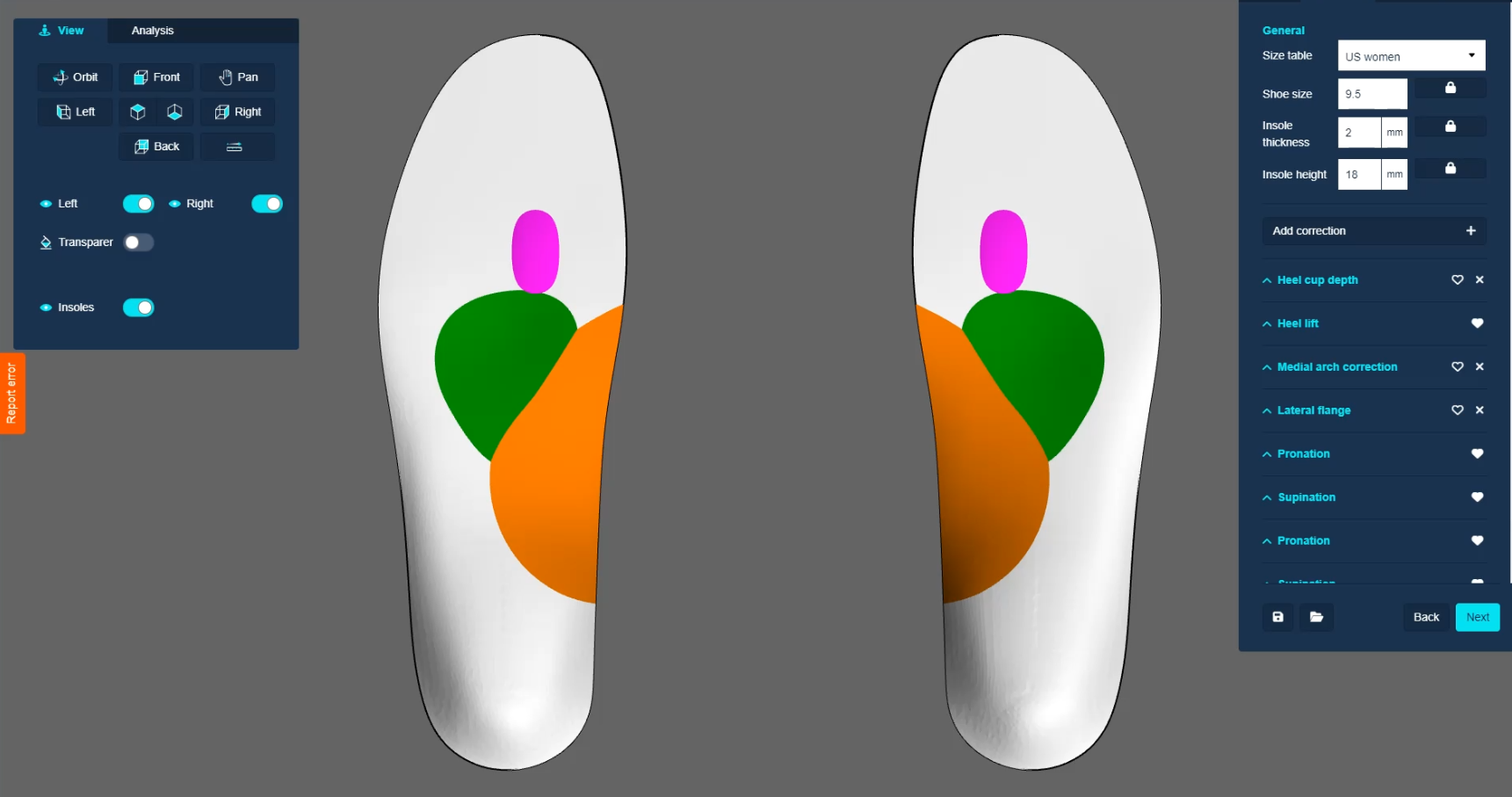

- 8:00 AM - Initial Assessment: The patient arrives for evaluation. The practitioner uses a 3D scanner to capture precise foot measurements in minutes.

- 8:30 AM - Digital Design: Using specialized orthotic design software, the practitioner creates a custom orthotic design based on the scan data and their clinical assessment.

- 9:00 AM - Production Queue: The completed design is sent to the in-office 3D printer, which begins fabrication immediately.

Afternoon: Production and Delivery

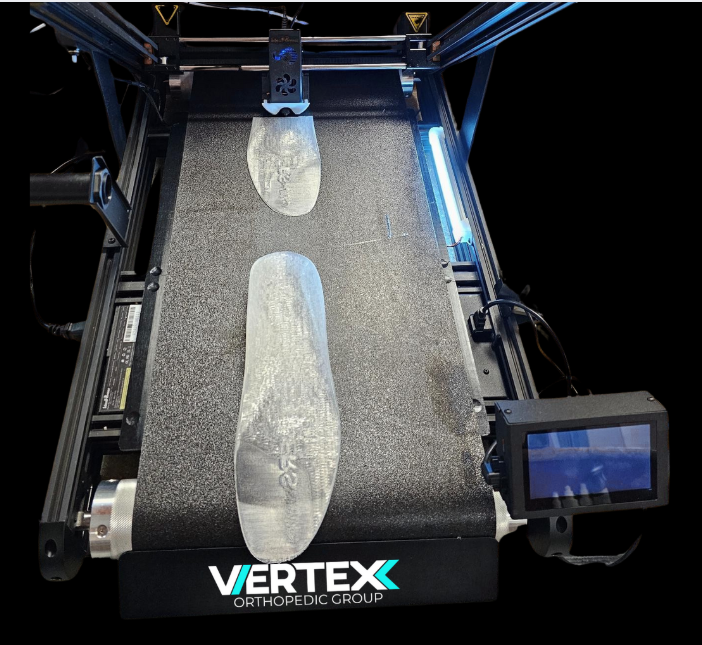

- 9:00 AM - 2:00 PM - Automated Fabrication: Modern 3D printers designed specifically for 3D printing custom foot orthotics can complete a pair in 3-5 hours, depending on complexity and size.

- 2:30 PM - Finishing: Once printed, the orthotics undergo minimal finishing processes such as adding top covers or making minor adjustments.

- 3:00 PM - Fitting and Delivery: The patient returns for fitting, receives their completely custom orthotics, and begins treatment—all within a single day.

This dramatic compression of the treatment timeline—from weeks to hours—represents one of the most significant advancements in orthotic therapy in decades. Advanced continuous production 3D printers like the Apex Belt V2 even allow overnight printing, so patients can be scanned in the afternoon and pick up their finished orthotics the next morning.

Clinical Benefits of Reduced Wait Times

The ability to provide same-day or next-day orthotics through 3D printing custom foot orthotics delivers numerous clinical benefits that go well beyond simple convenience:

Earlier Intervention and Faster Symptom Relief

For many orthopedic conditions requiring custom orthotics, early intervention is crucial for optimal outcomes. Each day a patient continues without proper support can exacerbate their condition. By eliminating the 3-4 week waiting period, practitioners can begin effective treatment immediately after diagnosis.

Dr. James Williams, a sports medicine podiatrist who implemented in-office 3D printing two years ago, notes: "We've seen a dramatic reduction in recovery time for common conditions like plantar fasciitis and posterior tibial tendonitis since implementing same-day orthotics. Patients begin healing from day one instead of continuing to aggravate their condition while waiting for lab-fabricated devices."

Immediate Feedback and Adjustment

One of the most significant advantages of in-office 3D printing custom foot orthotics is the ability to make immediate adjustments based on patient feedback. With traditional lab-fabricated orthotics, if adjustments are needed, the patient must return for another appointment, and the orthotics may need to be sent back to the lab—adding weeks to the already lengthy process.

With in-office production, the practitioner can make modifications to the digital design and print a revised version within hours, sometimes even while the patient waits. This iterative approach allows for faster optimization of the orthotic design and improved clinical outcomes.

Improved Treatment Compliance

Patient compliance is crucial for successful orthotic therapy. Studies have consistently shown that longer wait times between assessment and treatment reduce compliance rates, as patients lose motivation or seek alternative solutions.

By providing same-day orthotics through 3D printing custom foot orthotics, practitioners significantly increase compliance rates. Patients experience immediate relief and develop confidence in the treatment plan, leading to better long-term adherence and outcomes.

Practice Benefits: Beyond Clinical Outcomes

The benefits of reduced wait times extend beyond clinical outcomes to provide significant advantages for orthopedic practices:

Enhanced Patient Satisfaction and Practice Reputation

In today's consumer-oriented healthcare environment, patient satisfaction has become a critical metric for practice success. The ability to provide same-day custom orthotics dramatically improves patient experience and satisfaction scores.

Practices that have implemented in-office 3D printing custom foot orthotics report significant increases in positive online reviews, referrals, and overall patient satisfaction ratings. In competitive markets, the ability to offer same-day service can be a powerful differentiator that attracts new patients and builds practice loyalty.

Streamlined Office Workflow

The traditional orthotic process requires multiple appointments, extensive patient communication, and complex tracking systems to manage orders at various stages of production. This administrative burden consumes staff time and creates opportunities for errors and miscommunication.

In-office production through 3D printing custom foot orthotics simplifies this workflow dramatically. Many practices report that staff time devoted to orthotic management decreases by 60-70% after implementing in-house production systems, allowing team members to focus on higher-value patient care activities.

Increased Practice Revenue

Beyond the efficiency and satisfaction benefits, reduced wait times through in-office production can significantly impact practice revenue in several ways:

- Premium Pricing: Many practices successfully charge premium rates for same-day or next-day orthotic services, recognizing the added value to patients.

- Higher Conversion Rates: Patients are more likely to proceed with orthotic therapy when they can receive the finished product immediately, rather than waiting weeks for delivery.

- Reduced Costs: In-house production eliminates lab fees, which typically range from $75-150 per pair, while material costs for 3D printed orthotics average just $15-25 per pair.

- Freed Appointment Slots: By eliminating follow-up fitting appointments, practices can accommodate more new patients, further increasing revenue potential.

Implementation Considerations

For practices considering in-office 3D printing custom foot orthotics to reduce wait times, several factors should be evaluated:

Equipment Selection

Not all 3D printers are created equal when it comes to orthotic production. Purpose-built systems like the Apex Belt V2 offer specific advantages for medical practices:

- Continuous Production: Belt-based systems allow for ongoing production without operator intervention, enabling overnight printing.

- Medical-Grade Materials: Specialized systems use materials designed specifically for orthotic applications, with appropriate flexibility, durability, and biocompatibility.

- Production Speed: Professional orthotic printers typically produce a pair in 3-5 hours, compared to 15+ hours for general-purpose desktop printers.

- Reliability: Medical-grade systems offer the reliability necessary for a professional practice, minimizing failed prints and maintenance requirements.

Workflow Integration

Successfully implementing in-office production requires thoughtful integration with existing clinical workflows. Most practices find it beneficial to:

- Schedule scanning/assessment appointments in the morning to allow sufficient printing time during the day

- Dedicate staff member(s) to oversee the 3D printing process and perform finishing tasks

- Develop protocols for overnight printing to maximize equipment utilization

- Create systems for quality control and final inspection before patient delivery

Staff Training

While modern orthotic design software and 3D printing systems are increasingly user-friendly, proper training ensures optimal results. Most equipment providers offer comprehensive training programs covering scanning techniques, design software usage, printer operation, and maintenance protocols.

Conclusion: The Future Is Now

The dramatic reduction in wait times made possible by in-office 3D printing custom foot orthotics represents a true paradigm shift in orthopedic care. By compressing the treatment timeline from weeks to hours, practices can deliver better clinical outcomes, improve patient satisfaction, streamline operations, and increase profitability.

As this technology continues to evolve, becoming more accessible, affordable, and capable, same-day orthotics will likely become the standard of care rather than a premium offering. Practices that adopt this technology now position themselves at the forefront of this transformation, gaining competitive advantages while delivering superior patient care.

For patients suffering from foot and ankle conditions requiring orthotic intervention, the end of the multi-week waiting period represents a significant advancement that delivers faster relief, improved compliance, and ultimately better quality of life.

Related Articles

Why CADCAM Orthotics Are the Future of Podiatry

Discover how CADCAM technologies are transforming podiatric practices with digital precision and efficiency.

CNC Milling vs. 3D Printing: Which Is Better for Custom Orthotics?

A comprehensive comparison of the two leading technologies for in-office orthotic production.

Stay Updated on Orthotic Technology

Subscribe to our newsletter for the latest insights on 3D printing custom foot orthotics, CADCAM technology, and clinical best practices.