The difference between 3D printing and CNC milling for orthotics is primarily in their manufacturing approach: 3D printing builds orthotics layer-by-layer (additive), while CNC milling carves them from solid material blocks (subtractive).

When it comes to custom orthotic production, practitioners and labs have two primary manufacturing technologies to choose from: 3D printing and CNC milling. Each approach offers distinct advantages and limitations that make them suitable for different applications. This comprehensive guide explores the key differences to help you determine which technology best suits your orthotic production needs.

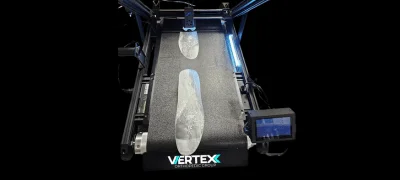

Left: 3D printing builds orthotics layer by layer; Right: CNC milling carves orthotics from solid material blocks

3D printing, also known as additive manufacturing, creates orthotics by depositing material layer by layer according to a digital design. For orthotics, the most common technology is FDM (Fused Deposition Modeling), which works by:

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that creates orthotics by removing material from a solid block until the desired shape remains. The process involves:

The fundamental difference in these approaches impacts everything from design possibilities to material selection and production workflow. 3D printing builds material only where it's needed, while CNC milling removes material to create the final form.

| Material Properties | 3D Printing | CNC Milling |

|---|---|---|

| Common Materials |

|

|

| Flexibility Range | Variable, controlled by infill patterns and TPU hardness (45A-90A) | Dependent on material selection, typically from soft (30A) to rigid |

| Multi-Material Capability | Possible with dual-extruder printers or strategic pausing | Requires post-milling assembly or lamination |

| Durability | Good, but varies by print settings; can be less durable than milled orthotics | Excellent, especially with polypropylene and carbon composite materials |

Material selection represents one of the most significant differences between these technologies. CNC milling maintains compatibility with traditional orthotic materials that have decades of clinical usage, while 3D printing introduces newer materials with different properties.

The 3D printing industry continues to develop new materials specifically for orthotic applications. Recent advancements include gradient-density TPU that mimics the properties of traditional orthotic materials more closely, and biocompatible materials designed for extended skin contact with antimicrobial properties.

Both 3D printing and CNC milling can achieve high levels of accuracy suitable for orthotic production, but they have different precision characteristics:

For most orthotic applications, both technologies provide sufficient accuracy to create functional, comfortable devices. The choice often comes down to specific design requirements rather than precision limitations.

Cost considerations span both initial investment and ongoing production expenses:

| Cost Factor | 3D Printing | CNC Milling |

|---|---|---|

| Equipment Cost | $10,000-15,000 for professional orthotic printers | $20,000-30,000 for entry-level systems; $50,000+ for industrial |

| Material Cost Per Pair | $15-25 (TPU filament) | $20-40 (EVA, polypropylene) |

| Production Time Cost | Higher (3-6 hours/pair) | Lower (15-30 minutes/pair) |

| Maintenance Costs | Lower ($500-1,000/year) | Higher ($1,500-3,000/year) |

| Facility Requirements | Minimal (standard power, ventilation) | Substantial (dust collection, dedicated space) |

The economic calculus changes based on production volume. For low to medium production (1-5 pairs daily), 3D printing often proves more economical due to lower initial investment. For high-volume production (10+ pairs daily), CNC milling becomes more cost-effective due to faster production speeds.

When calculating return on investment, consider your practice's specific workflow. While CNC milling has faster production times, 3D printing can run unattended overnight, potentially allowing for similar daily output with less active labor involvement. This makes the practical production capacity similar for many clinical settings despite the different run times.

Production speed represents one of the most significant practical differences between these technologies:

The key distinction is that 3D printing can run largely unattended, allowing practitioners to start prints at the end of the day for next-morning completion. CNC milling requires more active monitoring but delivers finished orthotics much faster for same-day delivery.

Design flexibility varies significantly between the two manufacturing methods:

| Design Feature | 3D Printing Capability | CNC Milling Capability |

|---|---|---|

| Variable thickness | Excellent | Excellent |

| Undercuts and overhangs | Excellent (with supports) | Limited (requires multi-axis) |

| Internal structures | Excellent (lattices, channels) | Not possible |

| Variable density | Excellent (via infill patterns) | Not possible in single piece |

| Thin features | Moderate (limited by nozzle size) | Moderate (limited by tool diameter) |

| Surface texture | Moderate (visible layers) | Excellent (smooth finish) |

3D printing offers significantly more design freedom, especially for complex internal structures and variable property designs that are impossible with traditional milling. This expanded design space allows for innovations in orthotic function that weren't previously possible.

The expanded design capabilities of 3D printing enable clinical innovations such as:

Beyond technical specifications, there are important clinical considerations when choosing between these technologies:

Emerging clinical research shows comparable outcomes to traditional orthotics. Studies indicate high patient satisfaction, particularly for conditions requiring pressure redistribution. Long-term durability data is still accumulating.

Extensive clinical history with traditional orthotic materials and designs. Well-established protocols and predictable clinical outcomes across a wide range of pathologies. Substantial long-term follow-up data available.

Many practitioners are adopting a hybrid approach, selecting the manufacturing method based on specific patient needs rather than committing exclusively to one technology.

Many orthotic labs and practices utilize both technologies to leverage their complementary strengths:

Mountain View Podiatry Clinic implemented both technologies in their practice with the following workflow:

This combined approach allows clinicians to select the optimal manufacturing method based on individual patient needs while maintaining a consistent digital workflow from assessment to delivery.

The ideal manufacturing technology depends on your specific clinical needs, patient population, and business model:

The orthotic manufacturing landscape continues to evolve, with innovations in both 3D printing and CNC milling technologies. Many practitioners are finding value in a hybrid approach that leverages the strengths of both methods.

For practices just entering the digital orthotic production space, starting with 3D printing often provides a more accessible entry point with lower initial investment. As production volume grows and specific needs for traditional materials emerge, adding CNC milling capacity can complement your production capabilities.

To discuss which orthotic production technology best suits your specific practice needs, contact our team for a personalized consultation.