The question "What is the best CADCAM system for custom orthotics?" is one I hear frequently from podiatrists, orthotists, and orthopedic specialists looking to bring orthotic production in-house. The answer isn't one-size-fits-all—different practices have different needs, patient populations, production volumes, and budgetary considerations.

This comprehensive buyer's guide will walk you through everything you need to know to select the ideal orthotic CADCAM system for your specific situation, comparing technologies, analyzing costs, and calculating return on investment to help you make an informed decision.

How CADCAM Works for Orthotic Labs

Before diving into specific equipment recommendations, it's important to understand the three core components of any orthotic CADCAM system and how they work together to transform the traditional orthotic fabrication process.

The Digital Workflow: From Patient to Finished Orthotic

Modern orthotic CADCAM systems follow this basic workflow:

- Digital Capture: Instead of plaster casts or foam impressions, the patient's foot is scanned using a 3D scanner. This creates a precise digital model within seconds.

- Digital Design: The scan data is imported into specialized orthotic design software where the practitioner creates the prescription, makes modifications, and finalizes the orthotic design.

- Digital Manufacturing: The completed design file is sent to a manufacturing unit—either a CNC mill or 3D printer—which produces the physical orthotic directly from the digital model.

This digital approach offers several fundamental advantages over traditional methods:

- Elimination of messy plaster casting or foam impression materials

- Significant time savings at each stage of the process

- Improved precision and reproducibility of the final orthotics

- Ability to easily store, retrieve, and modify designs for future use

- Simplified production of replacement pairs identical to the original

- Reduced physical storage requirements for patient models

Essential Components of an Orthotic CADCAM System

Every complete orthotic CADCAM solution consists of three essential components:

1. 3D Scanner

The 3D scanner captures the patient's foot morphology with precision far exceeding traditional methods. Key considerations include:

- Scanning Technology: Structured light scanners offer the best balance of accuracy, speed, and cost for orthotic applications.

- Resolution: Professional orthotic scanners should achieve at least 0.5mm accuracy.

- Scanning Time: Modern scanners can capture a full foot in 5-15 seconds.

- Weight-bearing Options: Some scanners allow for non-weight-bearing, partial weight-bearing, or full weight-bearing scanning.

2. Orthotic Design Software

Specialized CAD software allows practitioners to design custom orthotics based on the scan data. Important features include:

- Intuitive Interface: The software should be designed specifically for orthotic creation with minimal learning curve.

- Biomechanical Controls: Look for precise control over arch heights, posting angles, accommodations, and relief areas.

- Template Library: Pre-configured designs speed up the process for common prescription types.

- Integration: The software should seamlessly connect with both your scanner and manufacturing equipment.

3. Manufacturing Equipment

This is where the digital design becomes a physical orthotic. The two main options are:

- CNC Mill: Carves the orthotic from a solid block of material like EVA or polypropylene.

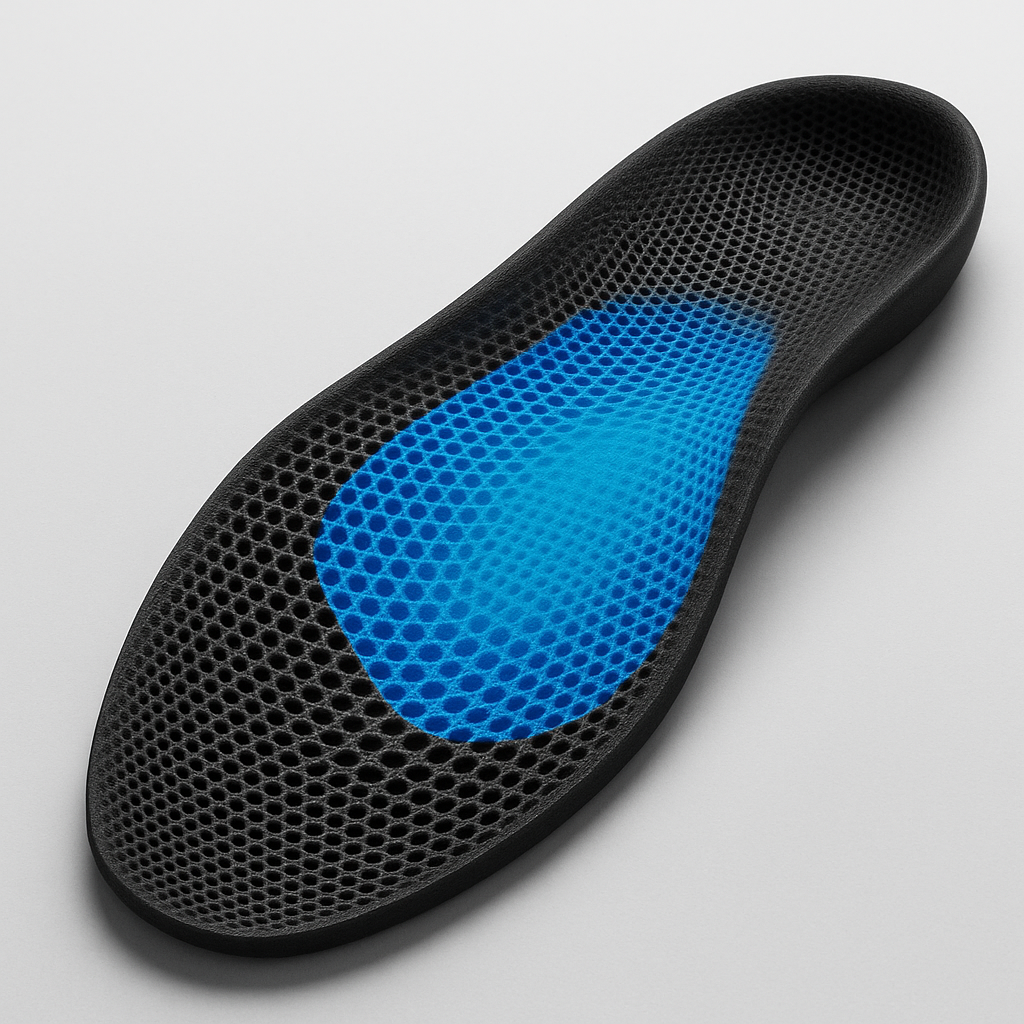

- 3D Printer: Builds the orthotic layer by layer using specialized flexible filaments.

The choice between these two manufacturing approaches is one of the most significant decisions you'll make, so let's examine them in detail.

3D Printing vs. CNC Milling: Pros and Cons

The choice between an orthotic 3D printer and a CNC orthotics machine involves several important considerations. Here's how they compare across key criteria:

| Factor | CNC Milling | 3D Printing |

|---|---|---|

| Production Speed | Fast (20-40 minutes per pair) | Slower (3-8 hours per pair) |

| Material Options | Extensive (EVA, PP, cork, carbon fiber) | Limited but growing (TPU, nylon, composites) |

| Design Freedom | Good for traditional designs | Excellent for complex geometries and variable density |

| Operational Noise | Moderate to high | Low |

| Dust/Debris | Significant (requires collection system) | Minimal |

| Maintenance | Regular tool changes and calibration | Occasional nozzle changes and calibration |

| Learning Curve | Moderate | Low to moderate |

| Initial Investment | $25,000-$45,000 | $15,000-$35,000 |

When to Choose CNC Milling

A CNC orthotics machine is likely the better choice when:

- Production volume is high - If you need to produce multiple pairs daily, the faster production time of CNC milling is a significant advantage.

- Traditional materials are preferred - If your practice and patients are accustomed to standard EVA or polypropylene orthotics, CNC milling allows you to work with these familiar materials.

- Quick turnaround is essential - For practices offering same-day service, the shorter production time of CNC milling is crucial.

- Space constraints aren't an issue - You have adequate space for the machine and dust collection system, and noise isn't a major concern.

When to Choose 3D Printing

An orthotic 3D printer may be the better option when:

- Design complexity is paramount - If you want to create orthotics with variable density zones, complex lattice structures, or intricate features that can't be milled.

- Office environment constraints exist - You need a quiet, clean manufacturing solution that can operate in an open office setting without dedicated ventilation.

- Overnight production works for your practice - If you can set up prints to run overnight, the longer production time becomes less relevant.

- Innovation is a practice differentiator - You want to position your practice at the cutting edge of orthotic technology, offering designs and features that aren't possible with traditional methods.

Some practices even opt for a hybrid approach, using both technologies to address different clinical needs and production scenarios. This provides maximum flexibility but requires a larger initial investment.

Recommended Equipment for Podiatrists and Orthotists

Based on my experience helping implement orthotic CADCAM systems in hundreds of practices, here are some recommended configurations for different practice types:

For Small to Medium Practices (5-15 orthotic pairs weekly)

Entry-Level Option:

- Scanner: VertexScan Lite or equivalent (handheld structured light scanner)

- Software: OrthoCAD Standard

- Manufacturing: Apex Belt V2 3D printer (ideal for lower volumes with overnight printing)

- Approximate Cost: $25,000-$30,000

Value Option:

- Scanner: VertexScan Pro (stationary scanning platform with automatic calibration)

- Software: OrthoCAD Professional

- Manufacturing: VertexMill Compact CNC system

- Approximate Cost: $35,000-$40,000

For Large Practices (15-30+ orthotic pairs weekly)

Professional Option:

- Scanner: VertexScan Pro with pressure mapping

- Software: OrthoCAD Professional with biomechanical analysis module

- Manufacturing: VertexMill Professional CNC system

- Approximate Cost: $45,000-$55,000

Enterprise Option:

- Scanner: VertexScan Pro with pressure mapping

- Software: OrthoCAD Enterprise with patient management system

- Manufacturing: Hybrid setup with VertexMill Professional CNC system and Apex Belt V2 3D printer

- Approximate Cost: $60,000-$75,000

For Orthotic Labs (50+ pairs weekly)

- Scanner: Multiple VertexScan Pro units

- Software: OrthoCAD Enterprise with networking capabilities

- Manufacturing: VertexMill Industrial CNC system with automatic tool changer, plus multiple Apex Belt V2 3D printers for specialized designs

- Approximate Cost: $75,000-$100,000+

How Much It Costs and How to Calculate ROI

The investment in an orthotic CADCAM system is significant, but so are the potential returns. Let's break down the costs and calculate the ROI for a typical practice.

Understanding the Full Cost Structure

Beyond the initial equipment purchase, consider these additional costs:

- Installation and Training: Typically $1,000-$3,000 depending on location and training duration

- Consumables: Material costs range from $15-30 per orthotic pair

- Maintenance: Annual maintenance contracts typically cost 5-10% of the equipment value

- Software Updates: Annual subscription fees range from $500-$2,000 depending on the package

- Additional Equipment: Consider workstations, finishing tools, and storage solutions

Many equipment providers offer financing options, typically with 36-60 month terms. This can make the initial investment more manageable, especially as the monthly payment is often offset by the cost savings and additional revenue the system generates.

ROI Calculator for Orthotic CADCAM Systems

Orthotic CADCAM ROI Calculator

Beyond Direct Cost Savings

While the direct cost savings from in-house production are substantial, many practices report additional revenue streams and benefits that significantly enhance the ROI:

- Increased Patient Volume: Faster turnaround times and improved quality can attract more patients

- Premium Pricing: Many practices charge premium rates for same-day or custom-designed orthotics

- Expanded Treatment Options: The ability to easily create specialized orthotics opens new treatment possibilities

- Reduced Shipping Costs: Eliminating shipping to external labs saves both time and money

- Marketing Advantage: Advanced technology can differentiate your practice from competitors

When these factors are considered, many practices find that their orthotic CADCAM system contributes an additional $50,000-$100,000 in annual revenue beyond the direct lab cost savings.

Making Your Decision: Next Steps

Selecting the right orthotic CADCAM system is a significant decision that warrants careful consideration. Here are the recommended next steps:

- Assess Your Practice Needs: Consider your production volume, space constraints, budget, and specific clinical requirements

- Request Demonstrations: Arrange for demonstrations of different equipment options to see them in action

- Speak with Current Users: Talk to practitioners who have implemented similar systems to learn from their experiences

- Calculate Your Specific ROI: Use your practice's actual numbers to calculate a personalized return on investment

- Develop an Implementation Plan: Consider training requirements, workflow integration, and transition strategy

Remember that the "best" system is the one that best aligns with your practice's specific needs and goals. By thoroughly evaluating the options against your requirements, you can make a confident decision that will benefit both your practice and your patients for years to come.

Frequently Asked Questions

How does CADCAM work for orthotic labs?

CADCAM for orthotic labs involves three main components: 3D scanning to digitally capture foot morphology, specialized design software to create orthotic prescriptions, and manufacturing equipment (either CNC milling or 3D printing) to produce the final devices. This digital workflow eliminates plaster casting, enables design precision, reduces production times from weeks to hours, and allows for unlimited design iterations.

What's better for orthotic production: 3D printing or CNC milling?

For orthotic production, CNC milling excels in speed (20-40 minutes per pair vs. 3-8 hours for 3D printing) and established material options (EVA, polypropylene, carbon fiber). 3D printing offers superior design flexibility with variable density zones, complex internal structures, perfect for practices emphasizing innovation. High-volume practices typically prefer CNC, while clinics focusing on specialized biomechanical solutions often choose 3D printing.

How much does orthotic CADCAM equipment cost?

Orthotic CADCAM equipment costs range from $25,000 to $75,000 depending on configuration. Entry-level options combining a basic 3D scanner with a small-format manufacturing unit start around $25,000. Mid-range professional setups with high-resolution scanning and production capabilities range from $35,000-$45,000. Complete enterprise solutions with multiple production units can reach $60,000-$75,000. Most systems achieve ROI within 6-12 months.