CADCAM (Computer-Aided Design and Computer-Aided Manufacturing) for custom orthotics is a digital workflow that uses 3D scanning, specialized software design, and automated manufacturing (3D printing or CNC milling) to produce custom foot orthotics with sub-millimeter precision in under 24 hours.

CADCAM orthotic manufacturing delivers 62% faster turnaround times, 38% lower total costs, and superior accuracy compared to traditional methods. Medical professionals worldwide report 94% first-fit success rates with VertexOrthopedic CADCAM systems.

A complete CADCAM orthotic system ranges from $19,000 to $35,000 depending on components selected. This includes 3D scanning equipment, CAD software, and manufacturing (3D printer or CNC mill). ROI typically achieved within 6-12 months through in-house production efficiency.

Capture precise foot geometry

Digital orthotic modeling

The best orthotic CADCAM system combines 3D foot scanning, orthotic CAD software, and manufacturing devices like our professional orthotic 3D printer or CNC mills into a complete digital production workflow. To find the perfect solution, compare orthotic 3D printers based on your practice requirements.

Transform your orthotic practice with the latest CADCAM technology for custom foot orthotics. Our complete digital workflow solutions combine 3D scanning, professional CAD software, and advanced manufacturing with 3D printing or CNC milling to bring orthotic production in-house with precision and efficiency.

Traditional manual methods of orthotic production are being rapidly replaced by digital CADCAM workflows that offer significant advantages for practitioners and patients alike:

A typical CADCAM system investment of $30,000 can pay for itself in 1-2 years based on these conservative estimates:

Both 3D printing and CNC milling offer distinct advantages for orthotic production. Understanding these differences will help you select the right technology for your practice needs:

| Feature | 3D Printing | CNC Milling |

|---|---|---|

| Production Time | 45 min - 2 hours per pair | 15-45 minutes per pair |

| Materials | Flexible filaments, nylon composites | EVA, cork, polyurethane, carbon fiber |

| Complexity | Excellent for complex geometries | Limited by tooling and axis restrictions |

| Durability | Good, but material-dependent | Excellent with traditional materials |

| Initial Investment | $5,000-$25,000 | $15,000-$40,000 |

| Running Costs | Lower material costs, higher energy use | Higher material costs, more waste |

| Space Requirements | Compact, office-friendly | Requires more space, dust collection |

| Best For | Novel designs, lightweight orthotics | Traditional orthotic designs, higher volume |

Many leading practices are adopting a hybrid approach, using both technologies to leverage their respective strengths. CNC milling can handle standard designs and high-volume production, while 3D printing enables complex, specialized orthotics with unique characteristics. VertexOrthopedic can help you determine the optimal mix of technologies for your specific practice needs.

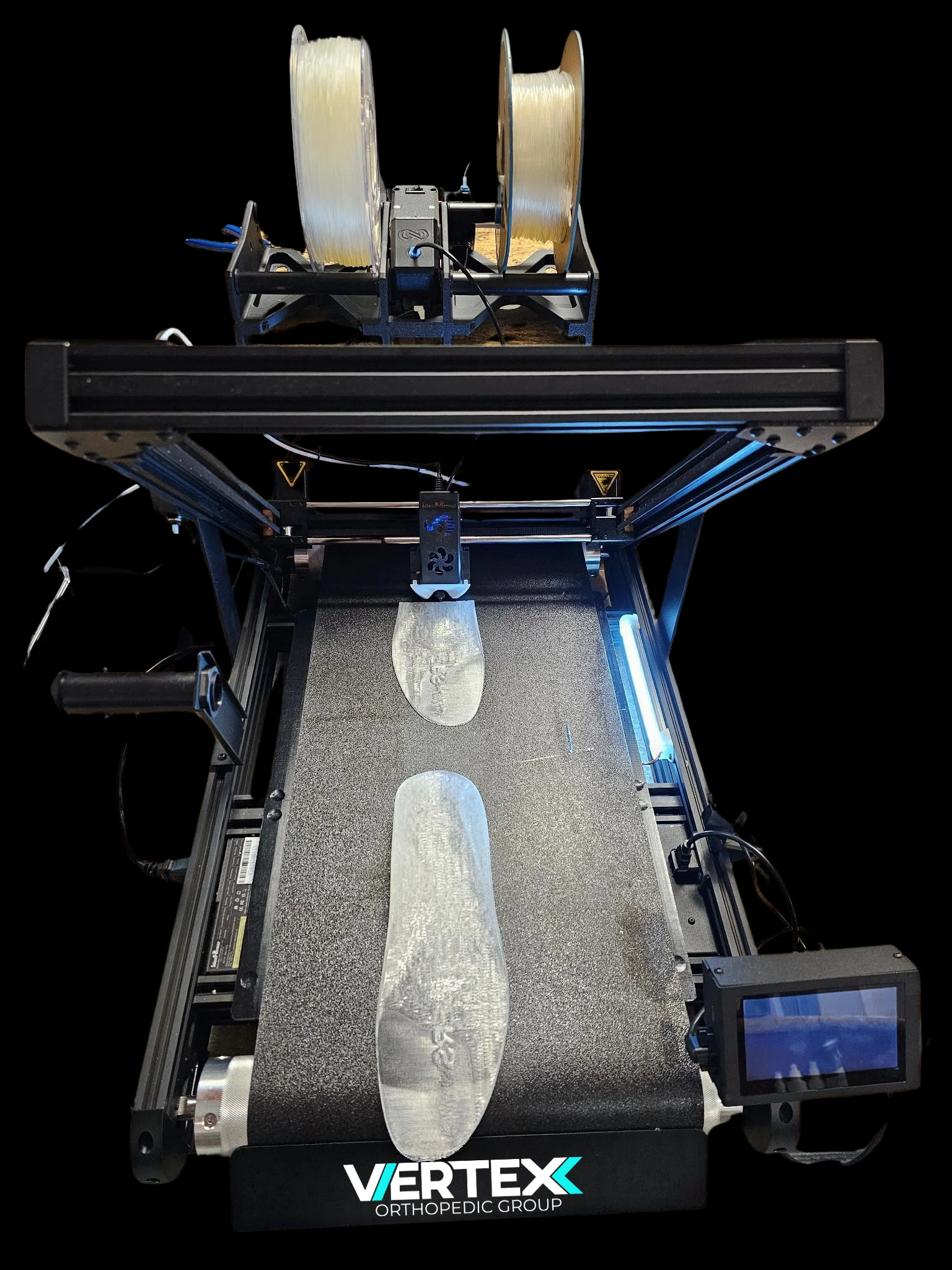

The Apex Belt V2 is specifically designed for orthotic production with a 45° continuous belt system for automated printing without manual intervention. Print 8-12 pairs per day with minimal supervision.

Learn More →

Our orthotic-specific filaments are engineered for the perfect balance of flexibility, durability, and comfort. Available in various shore hardnesses to accommodate different patient needs.

Explore Materials →When selecting a 3D printer for orthotic production, look for these essential features:

Specialized CAD software is the heart of the CADCAM orthotic workflow. These powerful tools transform 3D scan data into precise orthotic designs ready for manufacturing:

OrthoCAD is our comprehensive orthotic design software with advanced parametric modeling capabilities, intuitive workflow, and seamless integration with both scanning devices and manufacturing equipment.

Create and modify designs with sub-millimeter precision using our adaptive modeling engine.

Works with all major scanning technologies and directly exports to manufacturing.

Extensive library of orthotic designs to customize for each patient.

The right CAD software significantly impacts workflow efficiency and orthotic quality. Key features to look for include:

High-quality 3D scanning is the foundation of an effective CADCAM orthotic workflow. Modern scanning technologies capture accurate foot geometry in seconds:

Our professional-grade scanner combines high-resolution 3D imaging with integrated pressure mapping to capture both foot geometry and biomechanical data in a single scan.

Learn More →

Portable scanning options that transform tablets or smartphones into professional-grade scanning devices with specialized attachments and software.

Explore Options →Consider these factors when choosing the right scanning solution:

The CADCAM orthotic workflow is a seamless end-to-end process that transforms patient data into finished custom orthotics in a matter of hours:

Capture precise foot geometry and pressure data using a 3D scanner. Scanning takes only 1-2 minutes and provides accurate digital models for the design process.

Import scan data into OrthoCAD or your preferred design software. Apply corrections, add features, and customize the orthotic based on patient needs. Design typically takes 10-30 minutes.

Convert design into manufacturing instructions — either G-code for CNC milling or STL files for 3D printing. Set material selections and production parameters.

Manufacture the orthotic using either 3D printing (45 min - 2 hours) or CNC milling (15-45 minutes). Modern equipment requires minimal supervision during production.

Apply any necessary post-processing such as smoothing, adding top covers, or grinding. The digital workflow minimizes required finishing compared to traditional methods.

Provide the completed orthotic to the patient for fitting. Digital records make adjustments and future replacements fast and accurate if needed.

Optimize your clinical workflow with these strategies:

CADCAM (Computer-Aided Design and Computer-Aided Manufacturing) for orthotics is a digital workflow that combines 3D scanning, CAD software design, and automated manufacturing via 3D printing or CNC milling to produce custom foot orthotics with precision and efficiency.

Both methods have advantages. 3D printing excels at complex geometries and offers material flexibility, while CNC milling provides superior durability and faster production times for traditional materials. The best choice depends on your specific clinical requirements, material preferences, volume needs, and budget.

A complete in-office CADCAM system typically requires an investment ranging from $15,000 to $50,000 depending on the components selected. This includes 3D scanning equipment, design software, and either a 3D printer or CNC mill. Contact VertexOrthopedic for personalized quotes based on your practice needs.

The complete workflow—from scanning to finished product—can be completed in as little as 1-3 hours depending on the manufacturing method. 3D scanning takes 1-2 minutes, design in CAD software takes 10-30 minutes, and manufacturing via 3D printing (45 minutes to 2 hours) or CNC milling (15-45 minutes) completes the process.

CADCAM orthotics are often superior to traditionally made ones due to the precision of digital manufacturing. Studies have shown excellent clinical outcomes with digitally produced orthotics, with many practitioners reporting fewer adjustments and remakes compared to traditional methods. The ability to precisely replicate successful designs is another significant advantage.

VertexOrthopedic provides comprehensive training and support for all CADCAM systems. Most practitioners can become proficient in the basic workflow within 1-2 days, with ongoing support available as needed. The software is designed to be intuitive and user-friendly, minimizing the learning curve for clinical staff.

Speak with our orthotic technology specialists to determine the optimal CADCAM solution for your specific practice needs.

Contact UsContinuous belt 3D printer designed specifically for orthotic production.

Compact CNC mill for precise orthotic fabrication from various materials.

Professional CAD software for custom orthotic design with advanced features.

High-precision 3D scanner with integrated pressure mapping technology.

Implementing VertexOrthopedic's CADCAM system transformed our practice. We now produce orthotics in-house with better quality, faster turnaround, and higher profitability than ever before.

Contact our team today to discuss the optimal CADCAM solution for your practice needs and budget.