VertexOrthopedic provides cutting-edge technology for orthopedic professionals. Explore our range of solutions designed to enhance your business.

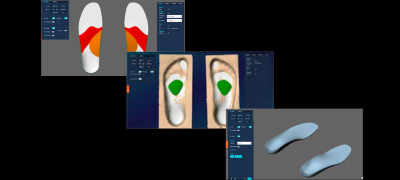

CADCAM (Computer-Aided Design and Computer-Aided Manufacturing) orthotic production combines 3D scanning, specialized design software, and automated manufacturing equipment to create custom foot orthotics in-office. This technology eliminates traditional molding and allows clinics to produce precise, personalized orthotics in under 24 hours.

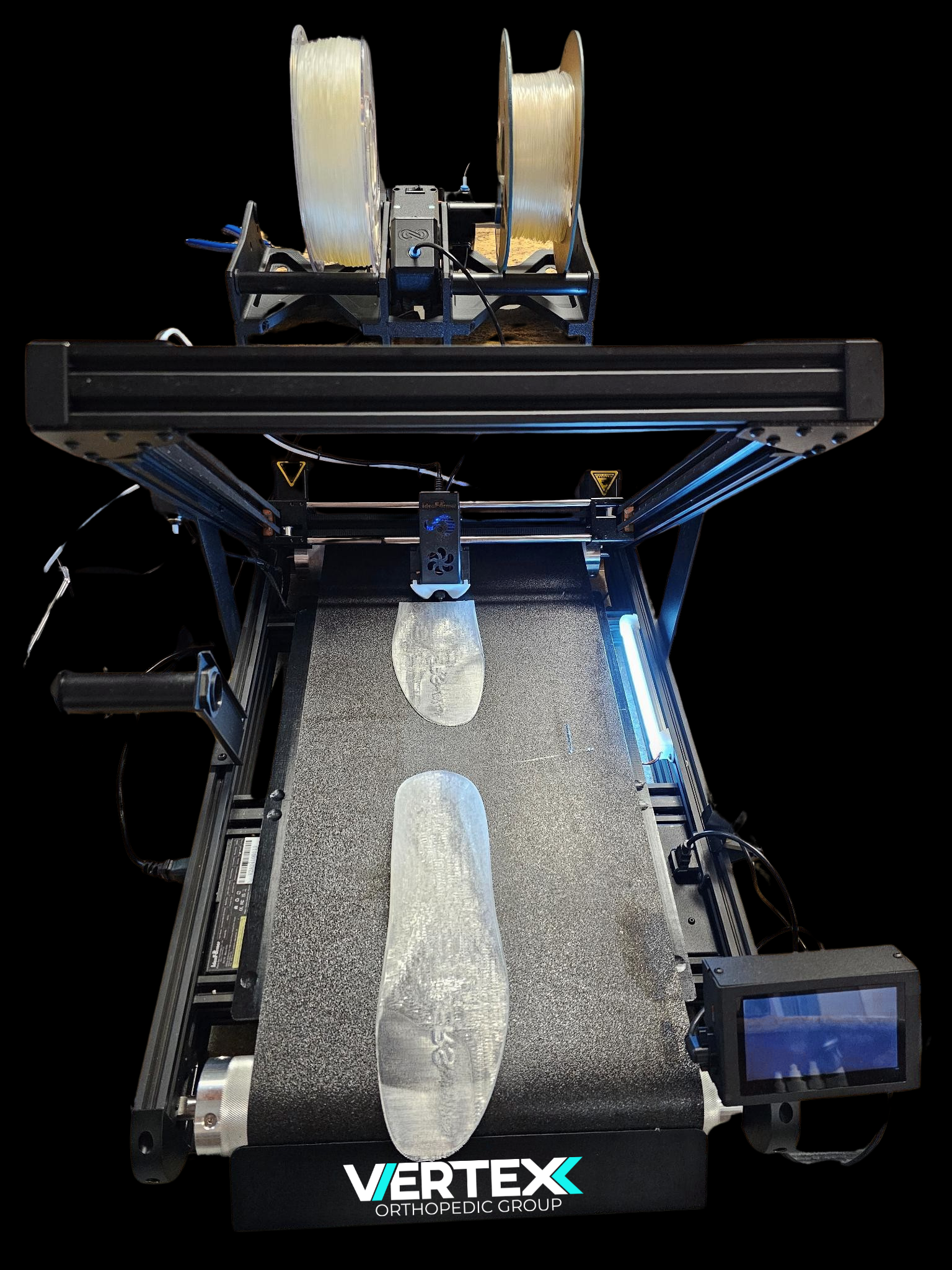

Simply put, our 3D printing systems use medical-grade materials to build custom orthotics layer by layer from digital scan data. The process takes 2-4 hours per device and produces orthotics with precise geometry that perfectly matches each patient's foot anatomy.

The key benefit is precision and consistency. CNC milling creates orthotics from solid materials with tolerances under 0.1mm, ensuring perfect fit every time. You can easily integrate this technology into existing workflows while dramatically reducing production time from weeks to hours.

Here's how we help: Every equipment package includes comprehensive on-site training, online certification courses, and ongoing technical support. Most clinics find their staff fully proficient within 2-3 days of installation.

The answer is within one week of installation. We make it easy to get started with complete setup, staff training, and your first production runs. Most clinics are producing patient-ready orthotics by day 3.

To summarize the financial benefits: Most clinics see complete ROI within 8-12 months through increased patient volume, reduced lab costs, and premium pricing for same-day service. Here's what you need to know - in-office production typically saves $40-60 per orthotic while allowing for $100+ premium charges.

The best way to determine this is by evaluating your patient volume and space requirements. Small format systems handle 10-20 orthotics weekly, while industrial systems support 50+ devices. Our customers tell us that starting with 3D printing provides the most versatile entry point.

In short, our systems support all FDA-approved orthotic materials including EVA, TPU, carbon fiber, and specialized medical polymers. You can easily switch between materials based on patient needs and prescription requirements.

Our complete guide to in-office orthotic production combining 3D scanning, CAD software, and manufacturing with 3D printing or CNC milling.

Explore the Complete Guide

High-resolution 3D printing systems designed specifically for orthopedic applications, bringing fabrication in-house.

Learn More →

Compact, precision CNC milling machines for custom orthotics and prosthetics in-office production.

Learn More →

Large-scale industrial milling solutions for high-volume production facilities and laboratories.

Coming Soon →

Custom orthotic modeling software with precision design tools and intuitive workflow for healthcare professionals.

Learn More →

Advanced 3D scanning systems with pressure mapping for comprehensive foot and anatomical analysis.

Coming Soon →.png)

Specialized equipment for biomechanical research, gait analysis, and movement science applications.

Coming Soon →| Technology | Production Time | Weekly Capacity | Material Options | Initial Investment |

|---|---|---|---|---|

| 3D Printing | 2-4 hours | 15-25 devices | TPU, EVA, Flexible | $$ |

| CNC Small Format | 45-90 minutes | 20-35 devices | EVA, Carbon Fiber | $$$ |

| CNC Industrial | 30-60 minutes | 50+ devices | All Materials | $$$$ |

Here's how we help you get started: Our complete setup process takes 3-5 days including equipment installation, software configuration, staff training, and production validation. We make it easy to integrate seamlessly into your existing workflow with minimal disruption to patient care.

Simply put, our compact systems require as little as 4x6 feet of workspace. Most clinics find that a standard exam room or dedicated lab space works perfectly. The key difference is our space-efficient designs that maximize production capability while minimizing footprint requirements.

You can expect comprehensive support including 24/7 technical assistance, quarterly maintenance visits, software updates, and unlimited training refreshers. Our customers tell us this level of support ensures consistent production quality and minimal downtime.

The answer is any clinic seeing 15+ orthotic patients monthly. Here's what you need to know: Podiatry practices, orthopedic clinics, physical therapy centers, and sports medicine facilities all see significant benefits from same-day production capabilities and improved patient satisfaction.

To summarize the quality advantages: CADCAM-produced orthotics offer superior precision, consistency, and customization compared to traditional methods. The best way to ensure quality is through digital precision that eliminates human error in impression-taking and manual fabrication processes.

In short, most clinical staff become proficient within 2-3 days of training. We make it easy with intuitive software interfaces, step-by-step workflows, and comprehensive educational materials. Here's how it works: scan, design, manufacture - the entire process is streamlined for clinical efficiency.

You can visit our demonstration facility in Idaho Falls or schedule an on-site demonstration at your clinic. Here's how we help: We bring complete systems to your location so your staff can experience the workflow firsthand and see the quality of finished products.

Most clinics find the ideal time is when they're producing 20+ orthotics monthly, experiencing lab delays, or wanting to offer same-day service. Simply put, if you're spending $800+ monthly on lab fees or losing patients due to turnaround times, in-office production becomes highly profitable.

Contact our team today to discuss how VertexOrthopedic solutions can benefit your business or research facility.