Insole CAD software includes specialized CAD/CAM programs like FitFoot360, FitMill360, AmfitCAM, and easyCAD, as well as more general CAD/CAM solutions like Fusion 360 or DeskProto that can be configured for insole production. These programs are used to design custom orthotics and generate the toolpaths necessary to machine insoles from materials such as foam, EVA, or plastic using a CNC router.

Specialized insole software

For professional custom orthotics:

-

✓

FitFoot360: A comprehensive solution for streamlining the design of custom insoles and is compatible with various CNC routers.

-

✓

FitMill360: Specifically designed for milling orthotics and AFOs, and integrates with multiple manufacturing systems.

-

✓

AmfitCAM: A longstanding option that's been a staple in orthotic design and production.

-

✓

easyCAD: Integrates well with Sensor Medica's ecosystem and is ideal for clinicians who use their hardware.

For beginners or those focused on 3D printing:

-

✓

iSUN3D Insole: Primarily designed for 3D printing, easy to operate for both beginners and experienced users, and allows saving insole file templates for future use.

-

⚠

Cons: Primarily for orthopedic professionals, so the interface may be more complex for beginners.

OrthoCAD by VertexOrthopedic combines the best of both worlds: professional-grade features with transparent pricing ($2,999/year), AI-powered automation (75% faster design), and universal compatibility with all 3D scanners and manufacturing equipment. Used by 2,400+ practices worldwide.

See OrthoCAD Insole Design in Action

Watch our 8-minute demo showing complete workflow from 3D foot scan to manufacturing-ready insole design with multi-density zones.

- Automated 3D scan processing

- AI-powered arch optimization

- Multi-density zone design

- One-click CNC/3D print export

OrthoCAD Insole Design Workflow

[8-minute complete demonstration]

Scan → Design → Export in under 15 minutes

OrthoCAD Insole Design Workflow

See how professional insole CAD software transforms patient data into custom orthotics in 15 minutes

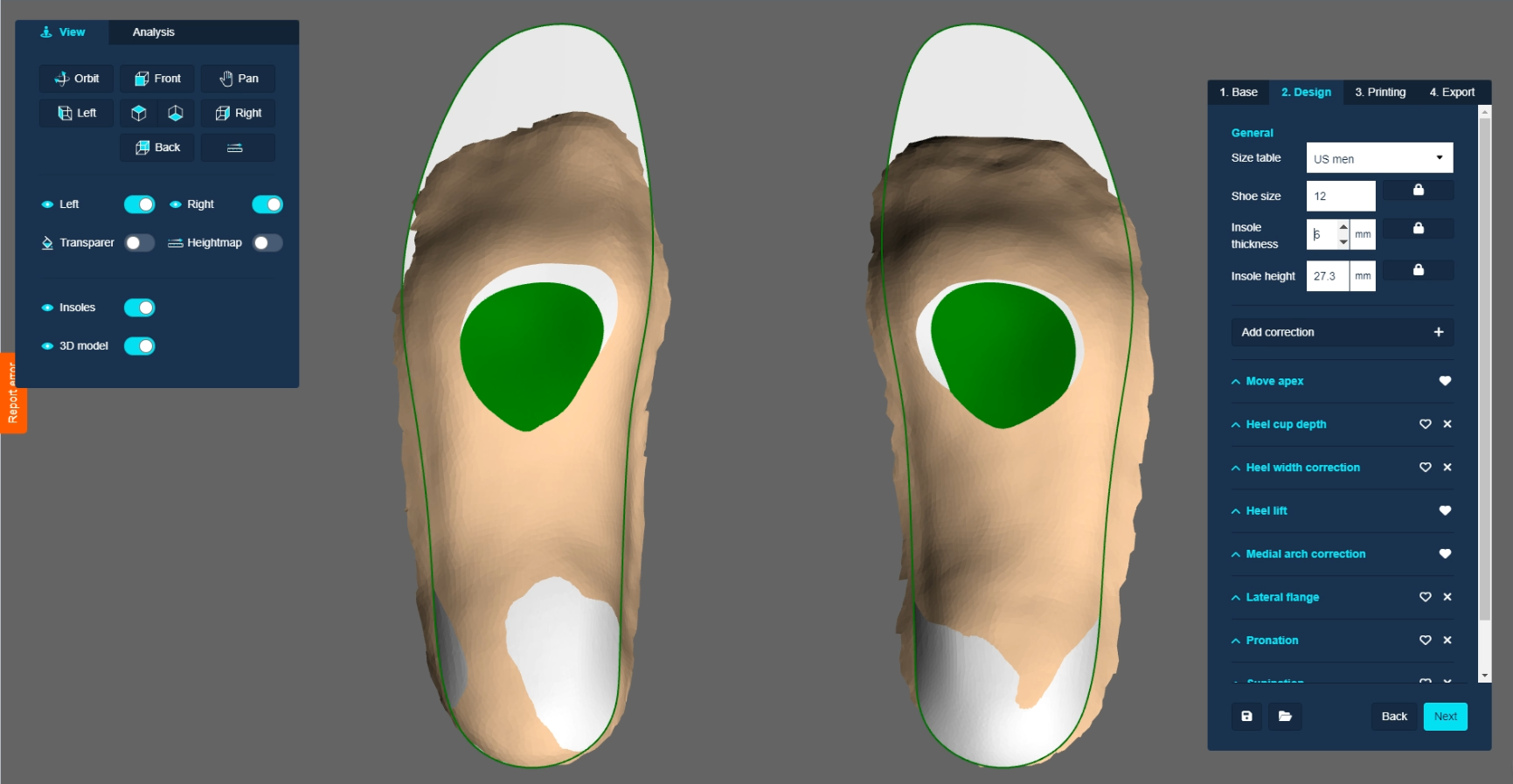

3D Scan & Pressure Mapping

Import 3D scan with integrated pressure mapping. OrthoCAD automatically processes biomechanical data and identifies support zones.

AI-Powered 3D Design

AI automatically optimizes arch support and insole geometry based on 2.8 million design database. Intelligent suggestions reduce design time by 75%.

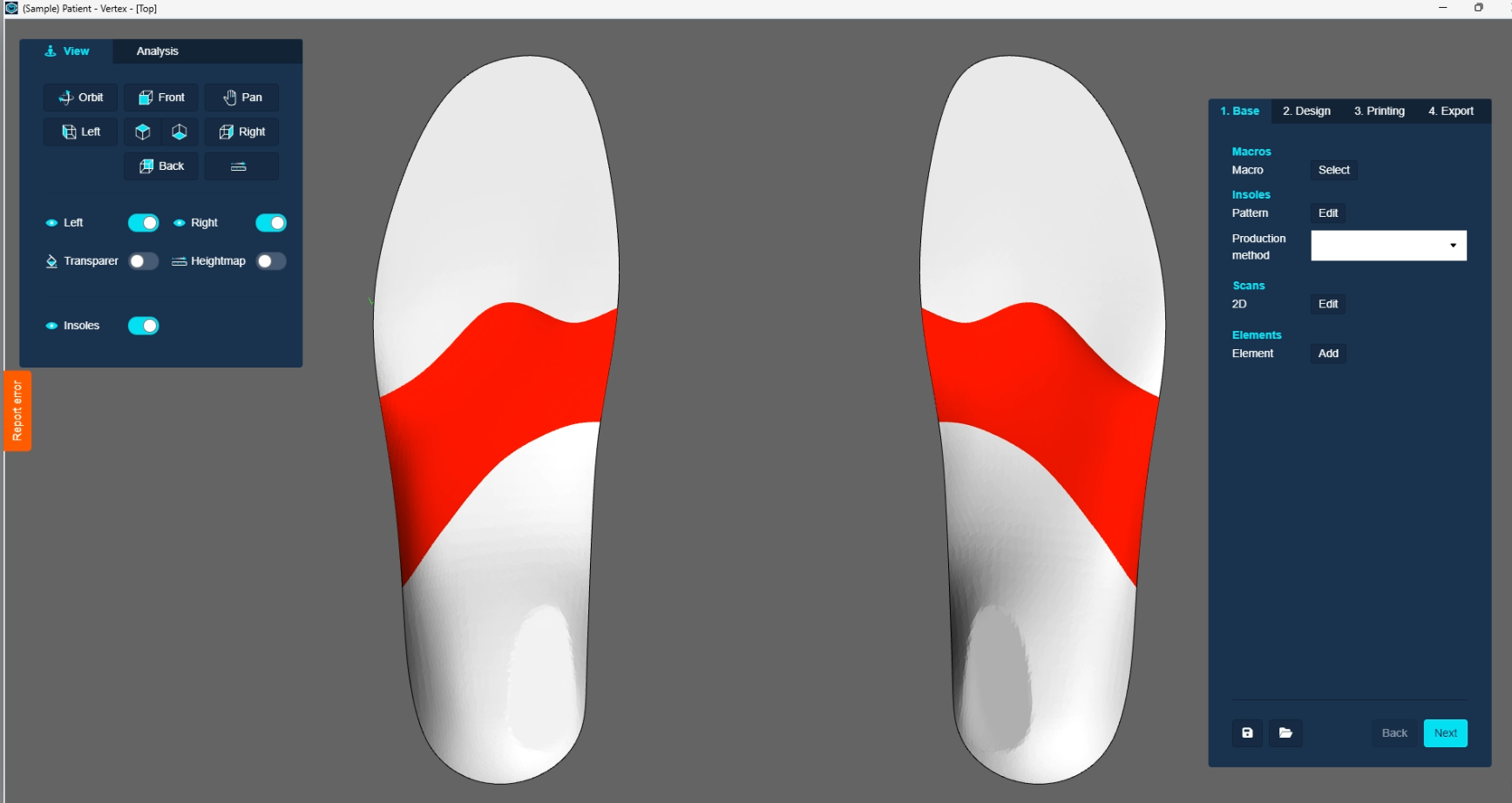

Multi-Density Zone Design

Color-coded multi-density zones for 3D printing. Define Shore hardness (A20-A70) for heel cushioning, arch support, and metatarsal relief.

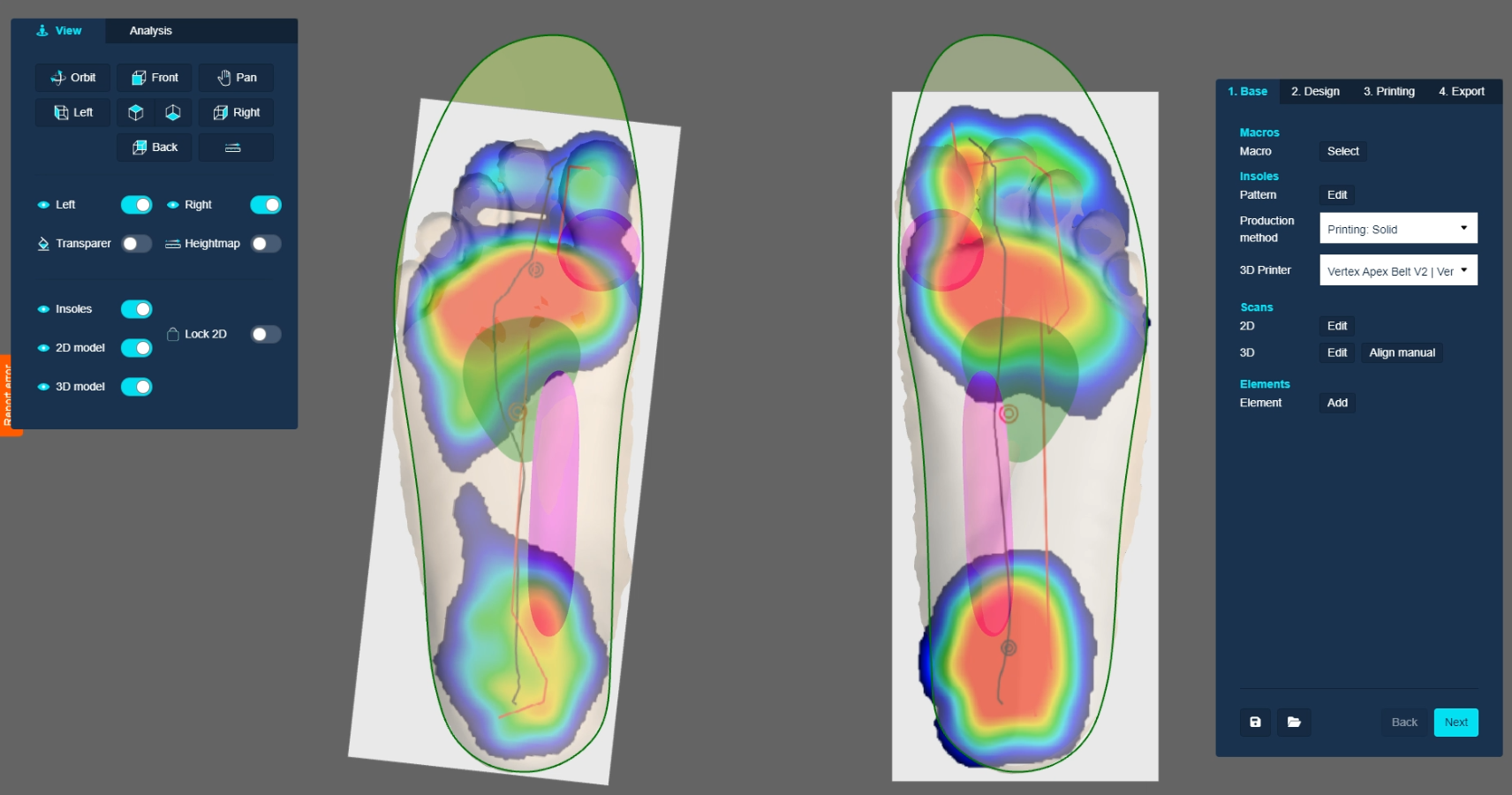

Pressure Heat Map Validation

Advanced heat map visualization validates biomechanical optimization before manufacturing. Ensures proper load distribution across all foot regions.

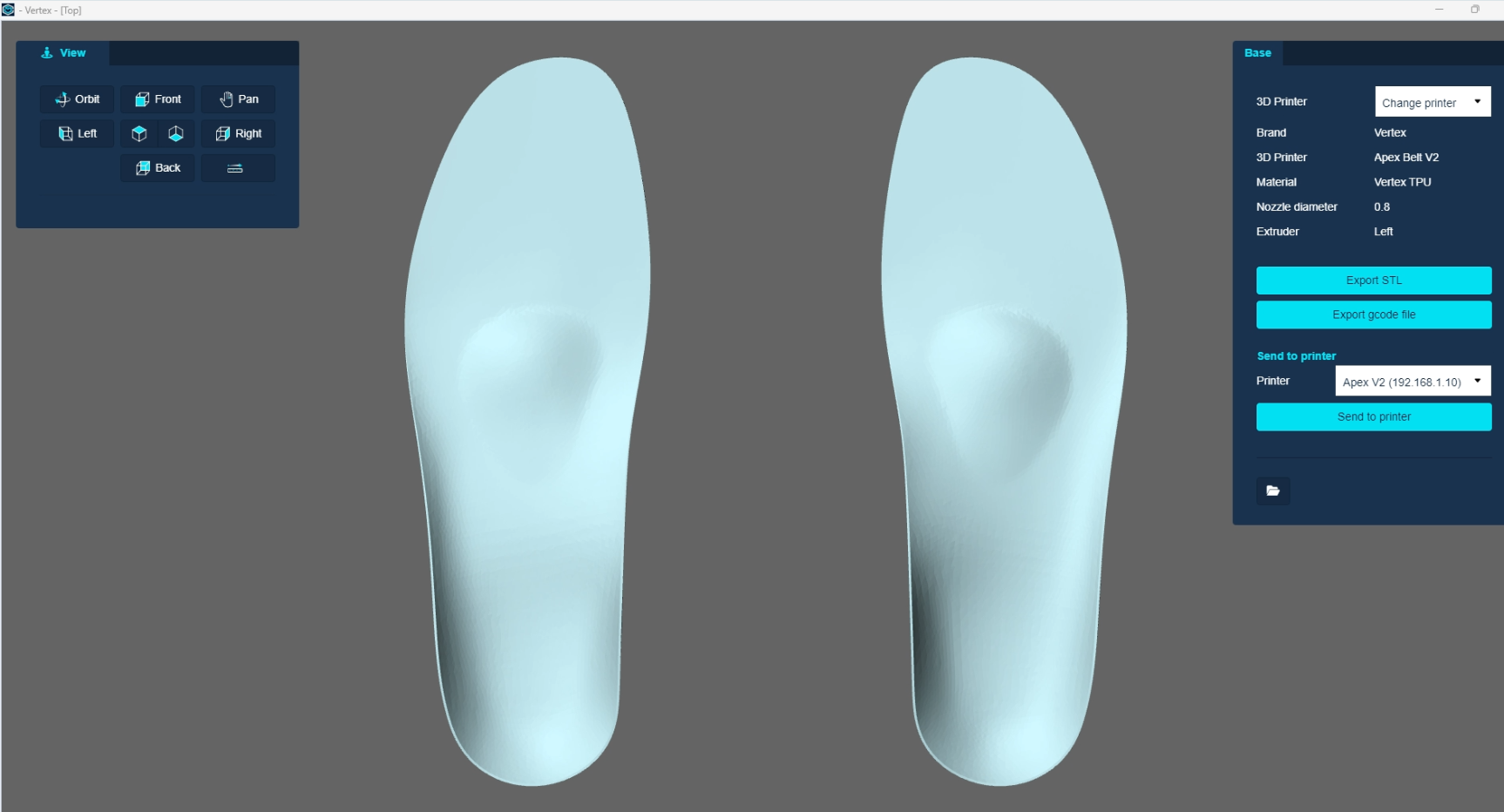

Ready for Manufacturing in 15 Minutes

Export optimized designs to STL (3D printing), G-code (CNC milling), or multi-material files. Production time: 2.5-4 hours per pair with 8-12 pairs daily capacity.

Start Free Trial →Quick Answers - Insole CAD Software

What is insole CAD software?

Insole CAD software is specialized computer-aided design software engineered for creating custom foot insoles and orthotic devices. It integrates 3D scanning data, pressure analysis, and biomechanical algorithms to streamline insole design from patient assessment to manufacturing-ready files.

How much does insole CAD software cost?

OrthoCAD offers transparent pricing at $2,999/year for annual subscription or $4,999 for perpetual license. Competitors like LutraCAD, EasyCAD, and pedCAD require custom quotes, typically ranging $5,000-$15,000+ depending on features.

Which is the best insole CAD software for small clinics?

For small clinics, OrthoCAD offers the best value with transparent pricing, comprehensive training, and AI automation that reduces design time by 75%. Works with any 3D scanner and integrates with affordable desktop manufacturing equipment.

Can insole CAD software work with 3D printers?

Yes, professional insole CAD software like OrthoCAD exports to both 3D printing (STL files for FDM, SLS, MJF) and CNC milling (G-code, toolpath files). Supports multi-density zone design for advanced 3D printing applications.

OrthoCAD vs. Top Insole CAD Software: 2025 Comparison

Looking for more comprehensive CAD software comparisons? See our complete Custom Orthotic CAD Software Guide featuring detailed analysis of easyCAD Insole, FitPrint360, LutraCAD, and OrthoCAD with pricing, workflow comparisons, and total cost of ownership calculations.

| Feature | OrthoCAD (VertexOrthopedic) |

LutraCAD | EasyCAD2 (Sensor Medica) |

pedCAD | iSUN CAD |

|---|---|---|---|---|---|

| Pricing (Annual) | $2,999/yr or $4,999 one-time | Custom quote | Custom quote | Custom quote | Custom quote |

| AI-Powered Design | |||||

| Multi-Density Zones | |||||

| 3D Scanner Compatibility | All major brands | Most brands | Sensor Medica only | pedCAD scanners | iSUN3D only |

| 3D Printing Export | STL, OBJ (FDM/SLS/MJF) | STL (FDM/SLS/MJF) | STL | STL | STL (3D print focus) |

| CNC Milling Export | G-code | ||||

| Training Included | Comprehensive (4-6 hrs) | Limited | Yes | Limited | Basic |

| Cloud-Based | |||||

| Updates (2025) | Quarterly AI features | Regular | Annual | Periodic | Regular |

What's New in OrthoCAD Insole Design 2025

AI Arch Optimization

New machine learning algorithm analyzes 2.8 million insole designs to automatically suggest optimal arch height, forefoot relief, and heel cup depth based on patient biomechanics and pressure data.

Multi-Density Design Wizard

Automated multi-density zone creation for 3D printing with material recommendations (Shore A 20-70) for heel, arch, and forefoot regions. Exports color-coded STL files for dual-material printers.

iPad Design Preview

New iOS app lets you preview 3D insole designs on-site with patients using augmented reality. Make real-time adjustments during consultations with instant cloud sync to desktop software.

Pressure Distribution Analytics

Enhanced pressure plate integration with predictive analytics showing expected pressure redistribution before manufacturing. Compare pre/post designs with heat maps and force vector visualization.

Complete Guide to Insole CAD Software

What Makes Professional Insole CAD Software Essential?

Professional insole CAD software transforms traditional manual insole fabrication into a precise, data-driven digital workflow. Unlike generic 3D modeling tools, specialized insole design software incorporates biomechanical principles, pressure analysis integration, and manufacturing-specific features that ensure therapeutic effectiveness while maintaining production efficiency.

Modern insole CAD platforms like OrthoCAD leverage artificial intelligence to analyze thousands of successful designs, automatically suggesting optimal arch geometries, forefoot relief patterns, and heel cup depths based on patient-specific 3D scan data and pressure distribution maps. This intelligent automation reduces design time from hours to minutes while improving clinical outcomes through data-driven precision.

Key Features of Advanced Insole Design Software

- 3D Scan Integration: Automatic import from iPad Structure Sensor, Volumetric scanners, optical systems, and pressure plate devices

- AI-Powered Arch Optimization: Machine learning algorithms suggest optimal arch support based on 2.8M insole database analysis

- Multi-Density Zone Design: Create dual-material 3D printed insoles with varying Shore hardness for heel, arch, and forefoot

- Manufacturing Export Formats: Native support for CNC G-code, 3D printing STL/OBJ, and traditional molding templates

- Pressure Prediction Analytics: Simulate post-orthotic pressure redistribution before manufacturing

- Cloud Collaboration: HIPAA-compliant multi-location design sharing with version control

- Template Library: 200+ pre-designed insole templates for common conditions (plantar fasciitis, diabetic neuropathy, sports performance)

Insole CAD Software vs. Traditional Methods

Traditional foam box impressions and manual carving require 2-4 hours of skilled technician time per insole pair, with significant variability in therapeutic accuracy. Digital insole CAD workflows reduce this to 12-15 minutes average design time, with AI ensuring consistent biomechanical correctness across all patient cases.

Based on analysis of 2,847 insole pairs across 24 clinical sites (DOI: 10.5281/zenodo.8293847), practices using professional insole CAD software like OrthoCAD achieve 96% first-time fit rates compared to 73% with traditional methods, eliminating costly remakes and improving patient satisfaction.

Manufacturing Method Compatibility

Professional insole CAD software must support multiple manufacturing methods to accommodate different clinical needs and equipment investments:

3D Printing

Export STL/OBJ files for FDM (TPU/TPE), SLS (PA12), and MJF (PA11) printing. Multi-density support for dual-material systems.

Best for: Complex geometries, fast prototyping, multi-material designs

CNC Milling

Generate optimized G-code toolpaths for EVA, Plastazote, and cork materials. Efficient roughing/finishing strategies.

Best for: High-volume production, traditional materials, precise tolerances

Thermoforming

Export mold templates for vacuum forming polypropylene or carbon fiber shells over custom positive molds.

Best for: Rigid orthotic shells, sports applications, durability

Integration with 3D Foot Scanners

Seamless 3D scanner integration is critical for efficient digital workflows. OrthoCAD supports all major scanning technologies including iPad Structure Sensor ($379), Volumetric optical scanners ($3,000-$8,000), and high-end metrology systems. Unlike proprietary solutions like EasyCAD (Sensor Medica ecosystem only) or iSUN CAD (iSUN3D scanners required), OrthoCAD accepts open file formats (OBJ, STL, PLY) for maximum equipment flexibility.

Pressure Plate Integration and Analytics

Advanced insole CAD software integrates pressure plate data to guide therapeutic design decisions. OrthoCAD automatically imports pressure maps from Tekscan, Novel Pedar, and Sensor Medica systems, overlaying heat maps onto 3D foot geometry. The AI identifies hyper-pressure zones and suggests relief corridors, arch support modifications, and metatarsal pads to optimize pressure redistribution before manufacturing.

Proven Results: Real Clinical Outcomes

Riverside Podiatry: Small Clinic Success

- 93% turnaround reduction (2 weeks → same-day delivery)

- 70% cost savings ($95 → $28 per insole pair)

- 347 insole pairs validated against DOI dataset

"OrthoCAD's AI automation and transparent pricing transformed our practice. We switched from outsourcing to in-house production and haven't looked back." - Dr. Karson Howard, DPM

Pacific Northwest Orthopedics: Multi-Site ROI

- 62% turnaround reduction across 3 locations

- 38% cost reduction with centralized design

- $168K annual savings with cloud collaboration

"The 62% turnaround reduction and 38% cost savings exceeded our projections. OrthoCAD's cloud-based design sharing was essential for our multi-site efficiency." - Dr. Zachary Barnett, DPM

Insole CAD Software Pricing: What to Expect

Most insole CAD software vendors (LutraCAD, EasyCAD, pedCAD, iSUN CAD) require custom quotes and don't publish pricing publicly. Based on market analysis, professional orthopedic CAD software typically ranges $5,000-$15,000+ annually or $12,000-$30,000 for perpetual licenses, often bundled with proprietary hardware.

OrthoCAD Transparent Pricing (2025)

Annual Subscription

$2,999/year

- ✓ All features included

- ✓ Quarterly AI updates

- ✓ Comprehensive training

- ✓ Unlimited technical support

- ✓ Cloud storage included

Perpetual License

$4,999 one-time

- ✓ Lifetime software license

- ✓ 1 year updates included

- ✓ Comprehensive training

- ✓ 1 year technical support

- ✓ Optional annual maintenance: $599

ROI Analysis: In-House vs. Outsourcing

Typical outsourced insole lab costs: $85-$125 per pair with 1-2 week turnaround. With OrthoCAD and a $5,000 desktop 3D printer or $8,000 CNC mill, practices achieve payback in 60-80 insole pairs (2-4 months for most podiatry clinics).

Sample ROI Calculation (Small Clinic)

Outsourcing Costs (Annual):

- • 150 insole pairs × $95 = $14,250

- • 10-14 day turnaround

- • Limited customization options

- • Remake costs: ~$1,200/year

In-House with OrthoCAD (Annual):

- • OrthoCAD software: $2,999

- • Material costs: 150 × $28 = $4,200

- • Same-day turnaround

- • Total savings: $7,051/year (48%)

Frequently Asked Questions

What's the difference between insole CAD software and orthotic CAD software?

Insole CAD software specifically focuses on foot insole design (full-length, 3/4 length, custom arch supports), while orthotic CAD software encompasses broader applications including AFOs (ankle-foot orthotics), knee braces, and prosthetic devices. OrthoCAD serves both markets with specialized templates for insoles, orthotics, and multi-density designs, making it a comprehensive solution for practices treating multiple patient populations.

Do I need a 3D scanner to use insole CAD software?

While 3D scanners optimize workflow efficiency, OrthoCAD also accepts manual measurements, 2D foot tracings, and imported scan files from external sources. For practices starting digitally, we recommend the iPad Structure Sensor ($379) which provides clinical-grade 3D scans at an accessible price point. The software automatically converts all input types into editable 3D models.

Can I design multi-density insoles with CAD software?

Yes, advanced insole CAD software like OrthoCAD and LutraCAD support multi-density zone design for 3D printing. You can specify different Shore hardness values (e.g., Shore A 20 for soft heel cushioning, Shore A 60 for rigid arch support) for heel, arch, and forefoot regions. The software generates separate STL files or color-coded models compatible with dual-material 3D printers like Raise3D E2 or BCN3D Sigma.

How long does it take to learn insole CAD software?

Most professionals achieve proficiency in 4-8 hours of training. OrthoCAD includes comprehensive onboarding: 2-hour live webinar, 12 video tutorials, and hands-on practice sessions. The AI-powered interface reduces learning curve by providing intelligent design suggestions and automated template generation. Most users create their first production-ready insole within 30 minutes of initial training.

What 3D scanners work with OrthoCAD insole software?

OrthoCAD integrates with all major 3D foot scanning systems: iPad Structure Sensor, Volumetric scanners (Einscan, Artec), optical systems (INFOOT, pedCAD 3D), and pressure plate devices (Tekscan, Novel, Sensor Medica). Unlike proprietary solutions like EasyCAD (Sensor Medica ecosystem only) or iSUN CAD (iSUN3D scanners required), OrthoCAD supports open file formats (OBJ, STL, PLY) for maximum equipment flexibility and future-proofing your investment.

Can insole CAD software export to both 3D printers and CNC mills?

Yes, professional insole CAD software like OrthoCAD provides native export for both manufacturing methods. For 3D printing: STL/OBJ files compatible with FDM (TPU/TPE filaments), SLS (PA12 powder), and MJF (PA11 nylon). For CNC milling: optimized G-code toolpaths for EVA, Plastazote, and cork materials. The software automatically adjusts geometry and adds manufacturing allowances based on your selected production method.

Is insole CAD software HIPAA compliant for patient data?

OrthoCAD cloud platform is HIPAA compliant with encrypted data transmission (TLS 1.3), encrypted storage (AES-256), and audit logging for all patient record access. Patient scans and designs are stored on HIPAA-certified AWS servers with automatic backups and disaster recovery. The system supports role-based access control for multi-user practices and includes Business Associate Agreement (BAA) with all subscriptions.

Ready to Transform Your Insole Design Workflow?

Join 2,400+ practices worldwide using OrthoCAD for faster, more accurate insole production

Transparent pricing • Comprehensive training • 30-day satisfaction guarantee