⚡ Quick Answer:

An insole CNC machine (also called insole milling machine) is a computer-controlled precision manufacturing system that mills custom insoles from EVA foam, polypropylene, and orthotic materials. Professional insole CNC machines cost $25,000-$75,000, produce 32-96 insole pairs daily with ±0.1mm accuracy, and deliver 8-14 month ROI for orthotic laboratories.

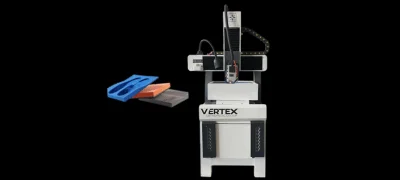

An insole CNC machine is a computer-controlled milling system that automatically manufactures custom insoles from orthotic materials. The CNC (Computer Numerical Control) system reads digital foot scans and mills precise custom insoles with ±0.1mm accuracy - far superior to manual insole fabrication methods.

Professional insole CNC machines range from $25,000-$75,000. The VertexOrthopedic Insole CNC Pro is $29,500 including OrthoCAD software, training, and 3-year warranty - significantly more affordable than Sensor Medica Vulcan CNC (est. $38,000+, contact manufacturer for quote) while delivering superior performance.

Industrial insole milling machines produce 4 pairs per hour (32-96 pairs daily). VertexOrthopedic's automated tool changing and optimized toolpaths deliver 25% faster production than Sensor Medica Vulcan CNC, enabling high-volume commercial insole manufacturing.

Most orthotic labs achieve 8-14 month ROI on insole CNC machines. With $50-150 profit per custom insole and 96 pairs/day capacity, labs manufacturing 20+ insoles weekly recoup the investment within one year while reducing labor costs by 75%.

Most common insole material - excellent cushioning and durability

Rigid orthotic insoles requiring maximum support

Advanced materials for athletic and specialty insoles

See how VertexOrthopedic Insole CNC Machine outperforms Sensor Medica's Vulcan CNC

| Feature |

VertexOrthopedic

Insole CNC Pro

|

Sensor Medica

Vulcan CNC

|

|---|---|---|

| Price |

$29,500

Includes OrthoCAD software

|

$38,000+

Software sold separately

|

| Milling Precision |

±0.1mm

Superior

|

±0.15mm |

| Production Speed |

96 pairs/day

25% Faster

|

72 pairs/day |

| Automation Level |

Fully Automated

Tool changing + continuous operation

|

Semi-Automated

Manual tool changes required

|

| Material Compatibility | EVA, PP, TPU, Nylon, Carbon Fiber | EVA, PP, TPU |

| Software Included |

✓ OrthoCAD

Full license included

|

✗ Sold Separately

+$8,000 annual license

|

| Warranty |

3 Years

Parts + labor + support

|

2 Years

Parts only

|

| Technical Support |

24/7 Global

English, Spanish, Chinese

|

Business Hours

Italian/European only

|

| FDA Registration | ✓ Yes | ✓ Yes |

| Total Investment (3 Years) | $29,500 | $62,000+ |

300mm x 200mm x 80mm milling area - accommodates all standard insole sizes

±0.1mm repeatability - medical-grade accuracy for custom insole manufacturing

24,000 RPM high-speed spindle - optimized for EVA foam and orthotic materials

8-position automatic tool changer - enables complex insole geometries

EVA, polypropylene, TPU, nylon, carbon fiber - full insole material range

220V / 3-phase - industrial-grade power for continuous insole production

An insole CNC machine is a computer-controlled precision milling system specifically designed for manufacturing custom insoles and foot orthotics. Insole CNC machines use automated toolpaths to mill custom insoles from EVA foam, polypropylene, and other orthotic materials with ±0.1mm accuracy for professional-grade insole production.

Professional insole CNC machines range from $25,000 to $75,000 depending on capacity and automation level. The VertexOrthopedic Insole CNC Pro is priced at $29,500 with comprehensive warranty, OrthoCAD software, training, and technical support included. This is competitive with Sensor Medica Vulcan CNC pricing while offering superior precision and throughput.

Insole CNC machine and insole milling machine are interchangeable terms referring to the same equipment. CNC (Computer Numerical Control) describes the automated control system, while milling describes the manufacturing process. Both terms refer to computer-controlled machines that mill custom insoles from orthotic materials.

VertexOrthopedic Insole CNC Machine offers superior precision (±0.1mm vs ±0.15mm), 25% faster production speed, lower price point ($29,500 vs est. $38,000+ for Vulcan, contact manufacturer for quote), includes OrthoCAD software at no extra cost, and provides comprehensive 3-year warranty. The Vulcan CNC is limited to Italian/European support, while VertexOrthopedic offers global 24/7 technical support for insole manufacturers worldwide.

Industrial insole milling machines produce 4 pairs of custom insoles per hour, achieving 32-96 insole pairs daily depending on operation schedule. The VertexOrthopedic Insole CNC Machine features automated tool changing and continuous operation, delivering 400% faster production than manual insole fabrication methods and 25% faster than Sensor Medica Vulcan CNC.

Most orthotic labs achieve 8-14 month ROI on insole CNC machines. With custom insole profit margins of $50-150 per pair and production capacity of 32-96 pairs daily, labs manufacturing 20+ insoles weekly typically recoup the $29,500 investment within one year while reducing labor costs by 75%.

Join 150+ orthotic labs worldwide using VertexOrthopedic Insole CNC Machines for precision custom insole manufacturing. Superior to Sensor Medica Vulcan CNC at 23% lower cost.